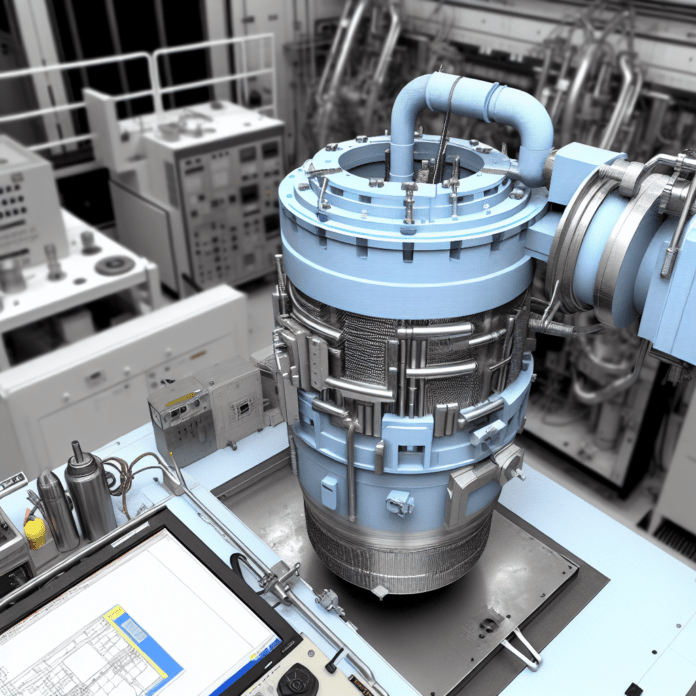

Researchers are turning to advanced 3D printing technologies to modernize the nuclear power sector, aiming to streamline the production of critical components and reduce the time and cost associated with traditional manufacturing methods. A recent breakthrough could be a game-changer for the energy industry.

3D Printing for Nuclear Reactor Components

Scientists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a novel method to 3D print reactor components using a technique called directed energy deposition (DED). This method allows for the precise layering of metal powders using a laser or electron beam, creating dense, high-performance parts with minimal waste.

Traditionally, manufacturing components for nuclear reactors involves casting and forging, which can take several months and incur high costs. The new 3D printing technique significantly reduces lead times, offering a faster route from design to deployment. This is particularly useful for producing complex geometries that are difficult or impossible to make using conventional methods.

Advantages of Additive Manufacturing in Nuclear Applications

The potential benefits of using 3D printing in the nuclear sector are substantial. For one, additive manufacturing (AM) enables rapid prototyping and iterative design changes, which can accelerate innovation and testing cycles. This is especially valuable in the nuclear industry, where safety and performance standards are stringent.

Additionally, AM processes like DED can produce components with tailored microstructures and optimized material properties. This level of control is crucial for ensuring the durability and reliability of parts exposed to high radiation and extreme temperatures inside a reactor.

ORNL’s research also focuses on qualifying printed parts for regulatory approval. The team is working closely with the Nuclear Regulatory Commission (NRC) and industry partners to ensure that 3D printed components meet the strict codes and standards required for use in nuclear systems.

Challenges and Next Steps

While the technology shows promise, several challenges remain. One major hurdle is the certification process, which can be lengthy and complex given the safety-critical nature of nuclear components. Researchers must also demonstrate the long-term performance of 3D printed parts under reactor operating conditions.

To address these issues, ORNL is conducting extensive material testing and performance evaluations. The goal is to build a robust database of material properties and performance metrics that can support broader adoption of additive manufacturing in the nuclear field.

Moreover, scaling up production capabilities and ensuring repeatability across different machines and facilities will be key to integrating 3D printing into mainstream nuclear manufacturing workflows.

Implications for the Future of Nuclear Energy

This 3D printing breakthrough comes at a critical time for the nuclear energy sector, which is undergoing a transformation driven by the need for cleaner, more sustainable power sources. New reactor designs, such as small modular reactors (SMRs) and advanced fast reactors, require innovative manufacturing approaches to be economically viable.

By enabling the rapid and cost-effective production of custom parts, additive manufacturing could play a pivotal role in bringing these next-generation reactors to market. It also opens the door to the refurbishment of aging nuclear facilities, where replacement parts are often scarce or obsolete.

As the world seeks to reduce carbon emissions and transition to low-carbon energy systems, technologies like 3D printing offer a path forward for nuclear power—making it more adaptable, efficient, and sustainable.

Source: Thomasnet