During a recent military exercise in the California desert, a group of San Diego-based manufacturers brought additive manufacturing directly to the battlefield. Their mission: use 3D printing to rapidly repair damaged military equipment in the field, keeping operations running smoothly and reducing costly downtime.

3D Printing Enhances Military Field Operations

In collaboration with the U.S. Navy and Marine Corps, two San Diego manufacturers—SD3D and Smartville—participated in a joint logistics field exercise at Twentynine Palms. The event, part of the Navy’s NavalX Tech Bridge initiative, aimed to test advanced manufacturing technologies in real-world conditions. Their mobile 3D printing labs were set up in the desert to assess how well additive manufacturing could support field maintenance and supply chain resilience.

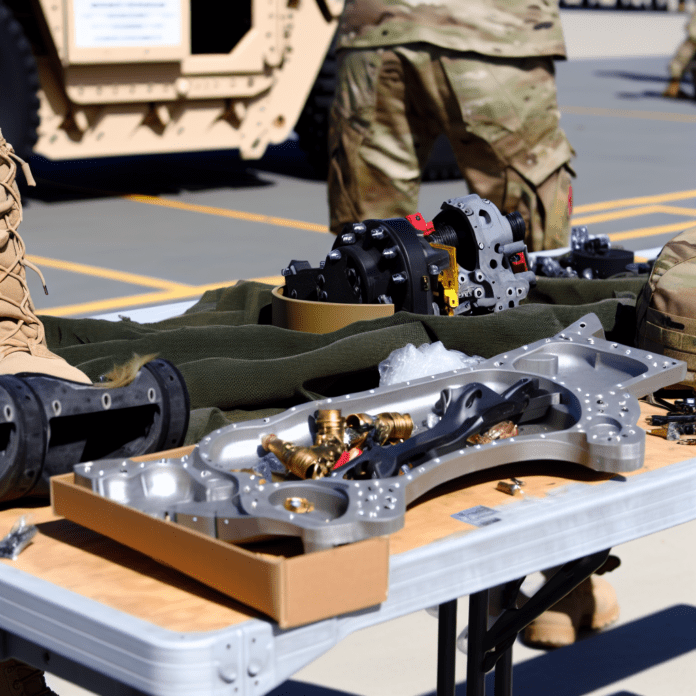

Over the course of the exercise, the teams were tasked with fabricating replacement parts on demand. For instance, when a Humvee’s mirror mount broke, instead of waiting days or weeks for a replacement, the team scanned the broken component, redesigned it using CAD software, and printed a durable plastic version within hours. The replacement was then mounted and tested in the field, proving the practical benefits of on-site manufacturing.

Mobile Additive Manufacturing Units in Action

SD3D and Smartville deployed mobile manufacturing units equipped with industrial-grade 3D printers, CNC machines, and other fabrication tools. These mobile labs were powered by solar energy and designed to operate in remote, off-grid environments. The goal was to mimic the conditions of forward-operating bases where supply lines are often stretched thin.

Smartville, which specializes in reusing electric vehicle (EV) batteries, also brought sustainable power solutions to the exercise. Their system used second-life EV batteries to store solar energy, powering the 3D printers and other equipment. This sustainable approach not only reduced reliance on fuel but aligned with the military’s push toward greener logistics.

Benefits of 3D Printing for Military Logistics

One of the biggest advantages of additive manufacturing in military applications is its ability to produce parts on demand. Traditional logistics chains can be slow and vulnerable, especially in combat zones. By printing parts in the field, the military can reduce downtime, extend the life of equipment, and increase mission readiness.

Moreover, 3D printing enables the creation of customized components that may no longer be in production. This is particularly valuable for aging equipment that still serves a purpose but lacks readily available spare parts. In the Twentynine Palms exercise, several such obsolete parts were reverse-engineered and printed successfully.

The Future of Additive Manufacturing in Defense

This field test is part of a broader effort by the U.S. Department of Defense to integrate advanced manufacturing technologies into its operations. The Navy and Marine Corps are exploring how additive manufacturing can support distributed operations, where small, agile units operate independently across vast areas. In such scenarios, the ability to produce parts locally can be critical to mission success.

San Diego’s role in this initiative is significant. The region is home to a growing ecosystem of defense-focused technology companies, many of which are pioneering applications of 3D printing and sustainable energy. By participating in exercises like these, local manufacturers not only showcase their capabilities but help shape the future of military logistics.

As the military continues to modernize, expect to see more mobile manufacturing units deployed in the field, powered by renewable energy and capable of fabricating everything from brackets to drone components. The Twentynine Palms exercise was just one step in demonstrating how additive manufacturing can keep the U.S. armed forces agile, responsive, and mission-ready.

Source: KPBS