What is the best material to use as a print bed?

This is one of those Questions we all ask at some point. For most of us, it’s asked out of frustration after a print pops off the bed 15 hours in. So what makes the best print bed? Sadly it’s not just one catch-all build plate. More a combination of 3 depending on what you print most often one print surface will be all you need, though. Most of us Print with 3 main types of filaments ABS, PLA and Nylon. More exotics are popping up all the time. These are the 3 most used print materials and if you can get nylon to stick then most of the exotics will stick pretty well.

Let’s get the elephant out of the room first. If all you print with is PLA. Blue painters tape or glass heated to 60-70c will probably cover your needs without costing you more than a few dollars. I personally don’t care for PLA. I tend to print things that get used more than displayed. Play just doesn’t stand up well mechanically. Yes, they are making some interesting exotics but I’ll stick with ABS or Nylon for most of my printing.

Glass vs Aluminum

Aluminum conducts heat the best. The drawback is it will scratch up or warp if you didn’t get one that is already warped. Borosilicate glass Takes longer to heat up but will give you a smoother print bed. This makes leveling much easier. When I print with PLA I use a glass print bed and only use a glue or hairspray when I have a print that lasts more that 3 hours. Personally, I Use the next material the most and it works for all of them.

BuildTak

If your aluminum build plate is flat buy a sheet of buildtak and apply to that If you want to have a removable print bed you can always apply it to a glass bed. The choice is yours I have used both. I’m not sponsored in any way by buildtak. It just works. It has its drawbacks, though. If you print your first layer too close getting the print to come off can result in damaging the sheet. For just under 30$ you get 3 sheets. If your are careful and don’t always print in the same spot over and over you will get a long print life out of one sheet. I have one sheet going on 400 hours right now with little sign of it wearing out. Now that’s all abs but Buildtak has a trick for nylon and we all use it already. A glue stick and a heated bed. A very thin coat and buildtak will hold nylon with no issues. Cleanup is easy with soapy water and a sponge. I have never had nylon over stick either. Soon as the bed cools it pops right off but while hot you’re not removing it.

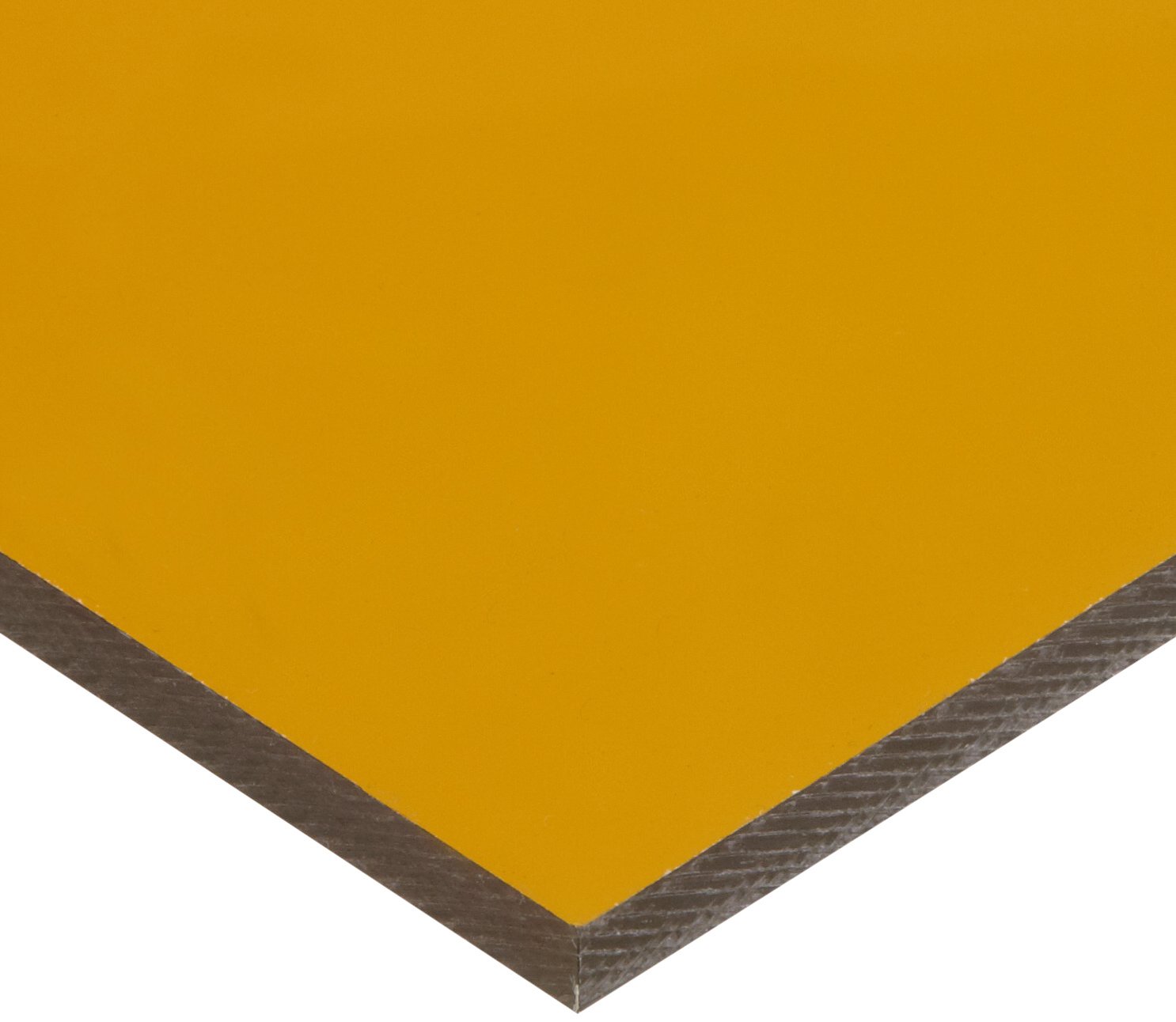

PEI

This is the best thing I have found to date. I swapped to this and I don’t think I’ll be replacing my buildtak sheet when it wears out. It’s another material that you apply to a print bed but it’s durable as well as tacky. The thing I don’t like about buildtak is that I can tear it or damage it. PEI can still be damaged but because it’s thicker and made of a harder material it can take more abuse. Careful on that first layer again This stuff will physically bond with some plastics so well they won’t come off without breaking them or the sheet. It takes some trial and error but once you have your build height. This stuff is the best hands down. I Ran out of nylon before I received my sheet so I couldn’t test it but I have 19 makerboxs worth of sample filaments and everything I have tried sticks first time every time and with plastics that need a heated bed as soon as it cools the part pops right off. I’m still testing this stuff but I’m over 100 hours on one sheet and nothing has let go yet.

Conclusion

I have to give the win to aluminum bed with PEI surface. You get the best heat transfer. Warped bottoms and parts popping off the bed mid-print is as best as I can tell non-existant. I would have to say buildtak has a longer track record so time will tell whether PEI becomes my go to surface material. Signs are good, though. Both of these options are under 30$ with buildtak you get 3 sheets for that which can last a very long time. PEI comes in around 20 with the 3m sheet you need to buy but it’s 12×12 so if you have a large bed you’re ahead of buildtak in price. I always say to check your print settings before buying something to get better adhesion but when that fails or you’re printing with nylon I would give these a try.

Sources

PEI

Buildtak

Hatchbox Filament

This filament has never failed me. I ran all my tests using hatchbox PLA and ABS first. I don’t like spending a lot on filament. This is one of the best low-cost filaments on the market.

I didn’t know things could pop off during printing. Thanks for the great information.

I’ll give this PEI a try.

I usually use a 4mm glass with an liquid called “A-Bond”, which is a special glue for 3dprinting. on PLA, ABS+ and PETG there is no warp, but nylon and common abs, i need to add some brim.

I have used PEI, Glue, ABS Slurry, Buildtak, and LokBuild. I really like the LokBuild. It is similar to Buildtak and seems to have a tougher surface, (takes abuse very well, as opposed to Buildtak). It does have a down side to it. it is more expensive that Buildtak. I figure I could buy 3 sheets of Buildtak and still pay less that 1 sheet of Lokbuild.

If you have adhesion issues with your printed objects, Buildtak is the way to go.

Forget about Glue, Slurry, Blue tape, PEI.

One of the problems with aluminum beds is that they are made from thin stock, which is why it warps and heats up quick. Borosilicate glass, which is far substantial, heats up slower due to its’ mass and the bed heater not being properly matched. In other words, the manufacturers are cutting corners to keep costs down as a properly matched heater for Borosilicate glass will require a larger power supply, heavier gauge wires, safety features, etc. Until manufacturers take the time to properly size and match the components that make up these printers there will always be some issues the user must contend with. These issues open up a market for bandages that simply mask the real issue and increase the operation costs for users.

Peace!

Thanks for the info, Il be more informed when I can afford it.

Still using glass for PLA and ABS, printer is enclosed – hairspray for PLA and ABS slurry for ABS.

Question regarding heating the bed, glue & tape. Do you all typically use the blue tape and/or glue stick on an unheated bed? I’ve found when I use tape on a heated bed it bubbles and curls. I’ve actually been using a double-sided carpet tape on an unheated bed and it works pretty well. It sticks to the bed very well and is very tacky, sometimes to the point of it being hard to get the piece off. It is woven so it will leave a cross-hatch on the bottom of your build though. If you heat the bed it will stay adhered but it also peels off a bit easier when replacing it.

I’m torn on what kind of bed I need. I don’t want to start out with problems, having an aluminum bed that can warp makes me worry about the trouble ahead. If I buy a 3D printer with an aluminum bed I think my first upgrade will be the glass bed. I can wait for it to heat up. I have a lot of time on my hands. Once an aluminum bed warps is that the last time you can use it? I imagine so! I don’t have much money I can spend on my hobby so the first thing I’m going to try will be the glue stick and the cheap stuff but I think I will bite the bullet and buy the PEI first chance I get if/when the cheap stuff causes problems. PEI sounds like the perfect stuff! Thanks for your insight!