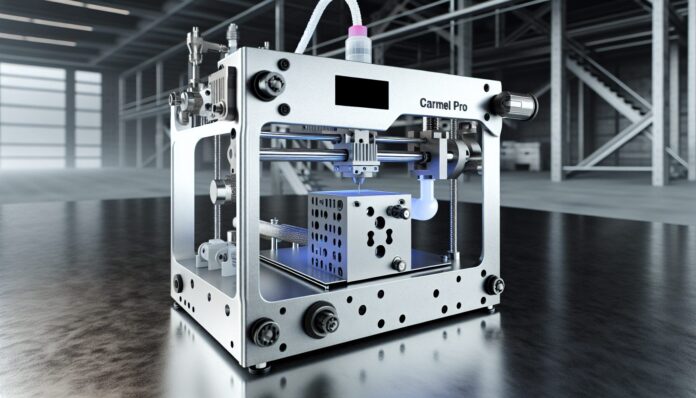

Israeli additive manufacturing company XJet has unveiled a new line of 3D printers aimed at making metal and ceramic additive manufacturing more accessible. The new Carmel Pro series is a cost-effective alternative to the company’s flagship Carmel production systems, offering the same high-quality NanoParticle Jetting (NPJ) technology in a more compact and affordable package.

XJet Carmel Pro: Affordable Metal and Ceramic 3D Printing

The Carmel Pro series includes two models: the Carmel 1400 Pro and the Carmel 700 Pro. These systems are designed to deliver the same precision and material capabilities as XJet’s high-end Carmel production printers but at a significantly reduced cost. This move is intended to lower the barrier to entry for companies looking to adopt metal and ceramic 3D printing technologies.

Both models use XJet’s proprietary NanoParticle Jetting (NPJ) technology, which enables the production of highly detailed parts with complex geometries. NPJ works by jetting ultra-fine droplets of a nanoparticle-laden liquid onto a build tray, followed by a drying and sintering process. This method allows for exceptional surface finish and accuracy, making it ideal for applications in medical, dental, aerospace, and industrial sectors.

Key Features and Technical Specifications

The Carmel 1400 Pro and 700 Pro are equipped with the same core NPJ technology as their production-grade counterparts. The main differences lie in the build volume and throughput, which have been optimized for prototyping and small-batch production. The Carmel 1400 Pro offers a larger build area, while the 700 Pro is more compact, catering to labs and smaller production environments.

According to XJet, the new Pro series maintains the same high standards of part quality, including fine detail resolution, smooth surface finish, and material purity. The systems are compatible with XJet’s existing range of materials, including stainless steel and zirconia, and are supported by the company’s soluble support material, which simplifies post-processing.

Expanding Adoption of NPJ Technology

By introducing the Carmel Pro series, XJet aims to expand the adoption of its NPJ technology beyond large-scale manufacturers to include research institutions, service bureaus, and small-to-medium enterprises. The reduced cost of ownership and operational simplicity make the Pro series an attractive option for organizations looking to explore the benefits of metal and ceramic additive manufacturing without the high upfront investment.

“We’re seeing growing demand for high-quality ceramic and metal parts across industries,” said Dror Danai, XJet’s Chief Business Officer. “With the Carmel Pro series, we’re making our technology more accessible to a broader range of users, enabling them to innovate and produce with the same level of quality as our production systems.”

Applications and Industry Impact

XJet’s NPJ technology is particularly well-suited for applications requiring high precision and complex geometries. In the medical and dental fields, it enables the production of custom implants and tools with biocompatible materials. In aerospace and automotive, it supports lightweight, high-strength components with intricate internal structures. The Carmel Pro series opens the door for more companies to leverage these capabilities in their R&D and production workflows.

As the additive manufacturing industry continues to evolve, accessibility and scalability are becoming key factors in technology adoption. XJet’s move to offer a more affordable line of printers aligns with this trend, potentially accelerating the use of metal and ceramic 3D printing across a wider range of industries.

Source: 3D Printing Industry