The following article was reposted with the permission of the Author Kodama Inc.

In this post, we want to share the story of how our latest product was copied before it became available to the market, our main lessons from the whole affair, and how we managed to come out of it on top.

But before we do that, here is an overview of the practice of copying (new) products.

Copying products.

Nicking ideas and going around product exclusivity isn’t anything new, nor is exclusive to China. Take the example of Robert Kearns who, in 1964 invented the intermittent motion windshield wiper, still used by most cars today.

When Kearns pitched his invention to the “Big Three” car makers in the US, they all turned him down. But by 1969, they were all using windshield wipers. They had copied the idea.

Kearns sued all manufacturers (and eventually won), but it was a slow and painful process.

Copying has always existed, and will always exist. After all, it’s why patents and copyright restrictions exist: to provide a window for the innovator to benefit from their own work, and create an incentive for people to create new product that advance our daily lives.

China is an especially challenging environment when it comes to product copying.

It’s where ideas meet manufacturing: international businesses go to China to partner up with factories that can create new products at reasonable prices, and that are ready for scale manufacturing at large volumes. This skews the balance of powers as the manufacturer can replicate the idea at any stage without being dependent from the inventor, whereas the business is reliant on their manufacturing partner throughout the process.

It also means that, once the assembly line and moulds are ready, there are no extra costs (apart from the ones per-unit) to add extra units to be manufactured “on the side”.

The legal system doesn’t help either: contracts, NDAs and exclusivity agreements, are all a good idea. But, say you are a US-based business.

Your choice is to bring a Chinese company to court in the US or…go to court in China.

In the first case, the court has no jurisdiction over the unfair manufacturer and…no way to actually enforce the contract. In the second case, you’d have to hire a Chinese lawyer, go to court in China and…well, hope for the best.

The cultural and language barrier makes copying easier: when internal communication isn’t clear all the time, it is easier to deceive and be deceived.

Cloning in 3D printing.

In the 3D printing space, blatant copying is very obvious, especially looking at what value Chinese manufacturers are bringing to the 3D printing industry and marketplace.

A word of warning: the images and stories you are about to see and read can be pretty upsetting to sensitive readers (especially if you’re a passionate maker).

Ok, not really. But cloning is an alarming phenomenon that shouldn’t allowed to become normal: not only entire businesses and jobs are affected by it; consumers miss out from the benefits of market competition and innovation too. So if you feel upset, that’s totally ok.

Let’s start with 2 extreme examples in the space: CR-10 and Prusa.

Both of these are very popular machine, but they both have also been milked and squeezed by clones that suddenly got to the market.

Prusa i3 became a popular 3D printer in the world by combining open source and simplicity. This made a flexible machine made of a few parts, but it also made it vulnerable to cloning. There are over 27 clones of the Prusa i3, most of them available on Amazon.

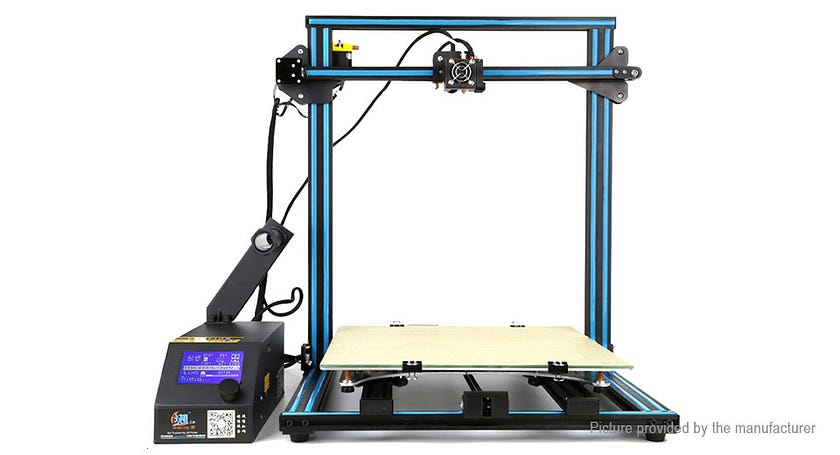

The original design of the Prusa i3 was so good, that even some of the variant imitation became popular in their own right and…got cloned or copied. Creality3D’s CR-10 combined the best characteristics of the Prusa i3 (or any of its clones) — affordability and quality prints — with an exceptionally large build volume and easy assembly.

Again, there are nearly 10 imitation machines os the CR-10 widely available to buy.

A copy of a copy (of a copy?).

No one is safe (not even cars).

This is not exclusive to 3D printing at all (nor to new brands): all sorts of products are being copied, including cars. Land Rover’s Evoque got copied with an almost simultaneous release of the lookalike X7 by Chinese “LandWind”.

Jaguar Land Rover chief executive Dr Ralf Speth told Autocar magazine: ‘The fact that this kind of copying is ongoing in China is very disappointing. The intellectual property (IP) is owned by Jaguar Land Rover and if you break that IP then you are in breach of international regulations.’

The Chinese are famous for their cloned car designs. While the local market has been growing at double digit rates every year, some carmakers have stopped cloning European cars and designed their own. However, smaller firms still send their little spies to major auto shows with pencils and tape measures in hand.

It’s even 3 times less expensive to buy than the real thing, which makes us wonder if the Landwind X7 is held together by chewed bubblegum and tape.

Kodama’s (bad) experience with copying.

Kodama also got their first taste of product copying when one of our ex-engineers run away with the 3D models, revised the design slightly and tried to market the machine in the West and even licensed to Wahoo. Of course, in spite of signing a non-disclosure agreement and other contracts.

As a consequence of this, we also lost four of our key suppliers, as we couldn’t risk to have any more of our technology leaked. So we had to stop our collaboration and source a new supplier to make our PCBA, heated bed, smart and normal LCD screens: this set us back a few months, but it was a necessary step to protect the product and design, and make sure that delivery was up to standard.

Luckily, our community of backers were very supportive and pretty vocal about the knock-off printer:

The Kickstarter team itself was very supportive and helpful, and prevented the copy from being unveiled and launched on their platform: the campaign was rejected after being in contact with Kodama and listening to the community and Obsidian backers.

Kickstarter made it clear that they really want to foster a fair community of new and innovative products.

Down on their luck, their tried their next shot on Indiegogo, where their campaign didn’t get enough traction to raise enough funds. The community clearly reacted with dubious cautiousness.

Seeing how much the community and platforms care about making the process fair, and protecting creators and backers was very refreshing in the middle of a “uh-oh” moment.

This is exactly the point of this article: only by caring about the creative process you can protect the community and benefit from new innovations.

No matter where in the world it happens, copying transforms hard work and creative passion into a way to make money by shortcutting the process at everyone else’s expense: the creator losing the exclusive benefits of hard work and development, and the consumer, who can no longer benefit from fair competition and constant innovation.

Copying takes away the passion, work, and innovation, leaving money-chasing as the only driver.

Which do you choose to support?

— — — — — — — — — — — — — — — — — — — —

This was a good article highlighting some of the pros and cons of manufacturing in China. Thanks for sharing it Henry.

Wow, no other comments and only one vote. I guess no one else read this?…

It is providing an actual method by utilizing that the users are able to copy from the 3D printer that will provide all kind of latest fruitful features so that they can able to lunch it from Kickstarter and it will be really very fruitful for them. If they get any issue Epson error code 0xf1 that must be recovered by them.