As the construction industry seeks greener alternatives, researchers have unveiled a promising method to make 3D concrete printing more sustainable—by incorporating agricultural waste fibers. This innovation not only reduces the environmental footprint of concrete but also enhances its mechanical performance, paving the way for more eco-friendly building practices.

3D Concrete Printing Meets Sustainability

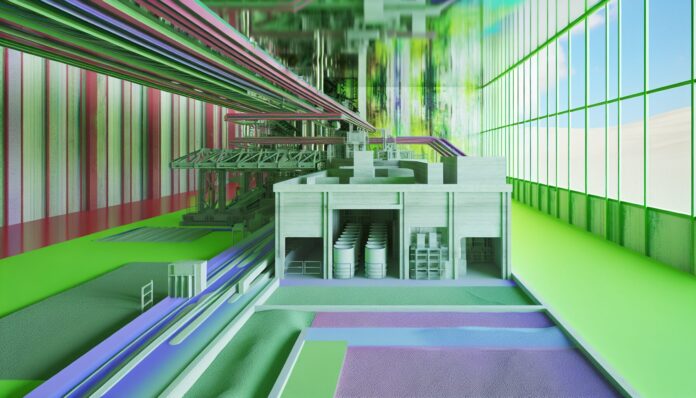

3D concrete printing (3DCP) has emerged as a transformative technology in the construction sector, offering design flexibility, reduced labor costs, and faster build times. However, traditional concrete production remains a major contributor to global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing.

To address this, a team of researchers from the Indian Institute of Technology Hyderabad (IITH) and RMIT University in Australia explored the use of agricultural waste fibers—specifically from corn husks, wheat straw, and rice straw—as sustainable additives in 3D printable concrete. Their findings were recently published in the journal Nature.

How Agricultural Waste Enhances 3D Printing Materials

The study focused on integrating natural fibers into the concrete mix to improve its rheological (flow) and mechanical properties. These fibers, which are typically discarded or burned, offer a renewable and biodegradable alternative to synthetic additives.

By treating the fibers with alkali and incorporating them into the concrete mix, the researchers observed improved printability, reduced cracking, and enhanced interlayer bonding. The fibers also contributed to better load-bearing capacity and durability of the printed structures.

Importantly, the use of agricultural waste fibers significantly reduced the carbon footprint of the concrete. The team reported a 20–30% reduction in CO2 emissions compared to conventional 3D printed concrete, making this approach a viable path toward carbon-neutral construction.

Applications and Future Potential

This sustainable 3D printing method holds immense potential for a range of applications, from affordable housing to disaster relief shelters and infrastructure in remote areas. The use of locally sourced agricultural waste not only cuts down on material costs but also supports circular economy principles by repurposing waste into valuable construction materials.

Moreover, the improved mechanical properties of the fiber-reinforced concrete make it suitable for load-bearing structures, expanding the scope of 3DCP beyond decorative or non-structural elements.

Looking ahead, the researchers plan to further optimize the mix design and explore other types of natural fibers. They also aim to scale up the technology for real-world construction projects, potentially revolutionizing how we build in a more sustainable and resource-efficient manner.

Challenges and Considerations

While the results are promising, there are still challenges to overcome. The variability in fiber properties depending on their source and treatment can affect consistency in the final product. Additionally, integrating these materials into existing 3D printing systems requires careful calibration to maintain print quality and structural integrity.

Nonetheless, the study marks a significant step forward in sustainable construction technology. By turning agricultural waste into a valuable resource, this approach aligns with global efforts to reduce emissions and promote greener building practices.

Source: Nature