In a breakthrough that could reshape the future of sustainable construction, researchers have developed a fast-curing, environmentally friendly alternative to traditional concrete—specifically designed for 3D printing applications. This innovation not only addresses the environmental impact of cement production but also enhances the speed and efficiency of additive manufacturing in the construction sector.

3D Printing Meets Sustainable Construction Materials

Concrete is the most widely used construction material in the world, but its production is responsible for nearly 8% of global carbon dioxide emissions. Traditional cement-based concrete requires high-temperature processing and emits significant greenhouse gases. In response, a team of researchers from RMIT University in Australia has created a novel geopolymer-based material that offers a sustainable alternative without compromising performance.

The new material is a geopolymer concrete substitute made from industrial byproducts such as fly ash and slag. These materials are activated using alkaline solutions, forming a binder that mimics the properties of traditional cement. Unlike conventional concrete, this geopolymer mix cures rapidly at room temperature, making it ideal for 3D printing applications where speed and precision are critical.

Fast-Curing and Environmentally Friendly

One of the standout features of this new material is its rapid curing time. Traditional concrete can take days to reach sufficient strength, but the geopolymer mix developed by the RMIT team sets in just a few hours. This fast-curing property significantly reduces construction time and energy consumption, making it a game-changer for on-site 3D printing of buildings and infrastructure.

Moreover, the material is composed of up to 80% recycled industrial waste, drastically reducing its carbon footprint. The researchers estimate that using this geopolymer concrete could cut CO2 emissions by up to 60% compared to traditional Portland cement. This makes it a compelling option for eco-conscious construction projects and governments aiming to meet sustainability targets.

Optimized for Additive Manufacturing

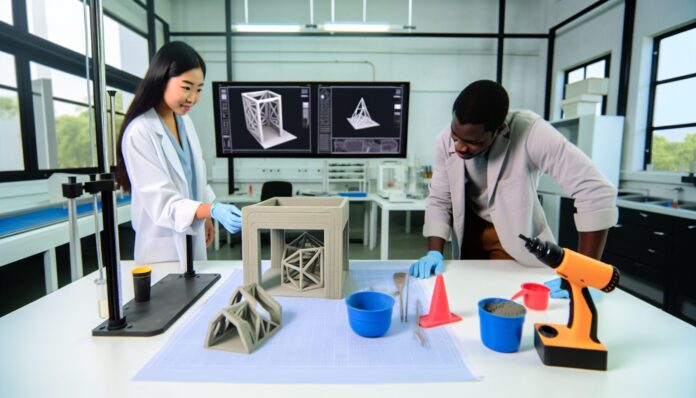

3D printing in construction requires materials that can be extruded smoothly, hold their shape after deposition, and cure quickly to support subsequent layers. The RMIT team tailored the rheological properties of their geopolymer mix to meet these demands. The result is a printable material that maintains structural integrity during the printing process and hardens rapidly without the need for external heat or chemical accelerants.

In lab tests, the material demonstrated excellent buildability and mechanical strength, making it suitable for a wide range of applications—from small-scale architectural elements to full-scale structural components. The researchers also noted that the material’s composition can be adjusted to suit different environmental conditions and printing requirements, offering flexibility for diverse construction scenarios.

Applications and Future Outlook

The potential applications for this 3D-printable geopolymer concrete are vast. It could be used in disaster relief to quickly build shelters, in remote areas where traditional construction materials are scarce, or in urban environments where reducing construction time and emissions is a priority. Additionally, the material’s compatibility with existing 3D printing technologies means it can be integrated into current workflows with minimal adjustments.

Looking ahead, the RMIT team plans to conduct field trials and collaborate with industry partners to scale up production. They are also exploring ways to further enhance the material’s properties, such as improving its resistance to extreme weather and increasing its load-bearing capacity. If successful, this innovation could play a pivotal role in the global shift toward greener, faster, and more efficient construction practices.

As the construction industry continues to embrace digital fabrication and sustainable materials, innovations like this geopolymer concrete substitute highlight the transformative potential of 3D printing in building a more sustainable future.

Source: Tech Xplore