Researchers have developed a groundbreaking 3D printing technique that enables the rapid fabrication of functionally graded materials (FGMs) using self-propagating reactions. This innovation could significantly accelerate the production of complex components for aerospace, biomedical, and energy applications.

Functionally Graded Materials in 3D Printing

Functionally graded materials are engineered to exhibit gradual changes in composition or structure over their volume, resulting in tailored mechanical, thermal, or chemical properties. These materials are highly sought after in industries where performance optimization is critical, such as aerospace, automotive, and biomedical engineering.

Traditional methods for producing FGMs are often time-consuming and limited in scalability. Additive manufacturing has emerged as a promising solution, but existing 3D printing techniques struggle to achieve the necessary material gradients efficiently and at high throughput.

Self-Propagating Reactions for Rapid Fabrication

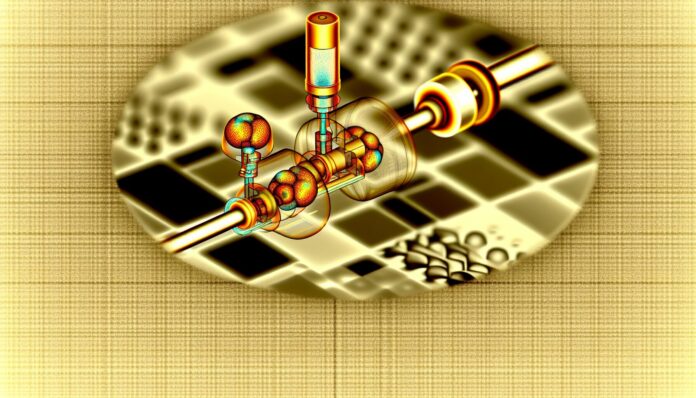

The new method, developed by a team of researchers and published in Nature, leverages self-propagating high-temperature synthesis (SHS) reactions to enable rapid, localized heating and material transformation during the printing process. By carefully controlling the composition of the feedstock and the printing parameters, the researchers were able to initiate and sustain exothermic reactions that propagate through the material, creating a gradient in composition and properties.

This approach allows for the continuous deposition of material with varying characteristics, all within a single printing process. The result is a high-throughput method capable of producing complex FGMs with unprecedented speed and precision.

Applications and Advantages of the New Technique

The implications of this technology are far-reaching. In aerospace, components with graded thermal resistance can better withstand extreme temperature variations. In biomedical implants, materials with varying stiffness can more closely mimic natural bone structures, improving integration and performance. Energy systems can benefit from components with tailored conductivity or corrosion resistance.

Compared to conventional additive manufacturing, this new method offers several advantages:

- Speed: The self-propagating reactions significantly reduce the time required to fabricate complex parts.

- Material Versatility: The technique supports a wide range of material combinations, including metals and ceramics.

- Precision: Fine control over reaction parameters enables precise tuning of material gradients.

- Scalability: The process is compatible with existing 3D printing platforms, making it easier to scale for industrial use.

Future Outlook and Research Directions

While the current demonstration is a significant step forward, further research is needed to optimize the process for different material systems and to ensure consistency and reliability in large-scale production. The integration of real-time monitoring and feedback control could further enhance the precision and repeatability of the technique.

As the field of additive manufacturing continues to evolve, innovations like this one highlight the potential of combining materials science with advanced printing technologies to unlock new capabilities. The ability to rapidly produce functionally graded materials could revolutionize how we design and manufacture high-performance components across multiple industries.

Source: Nature