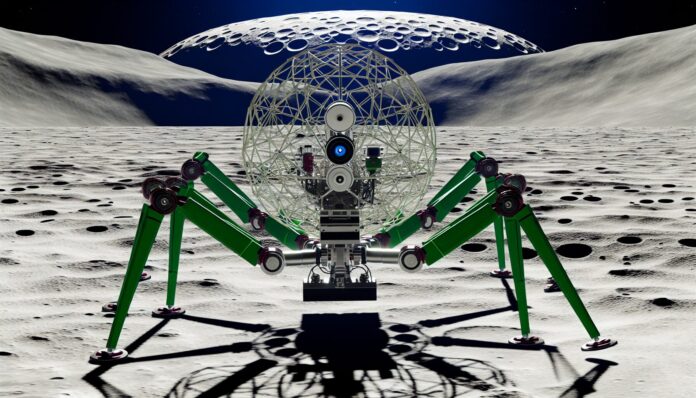

Imagine a future where homes on the Moon are built not by astronauts, but by autonomous, spider-like robots. That vision is inching closer to reality thanks to a NASA-funded project that could revolutionize how we construct habitats in space.

NASA and ICON: Pioneering Lunar 3D Printing

NASA has awarded a $57.2 million contract to ICON, a Texas-based construction technology company, to develop a robotic system capable of 3D printing structures on the Moon. The project, known as Project Olympus, aims to use lunar regolith—the Moon’s native soil—as the primary building material. This approach eliminates the need to transport heavy construction materials from Earth, significantly reducing mission costs and complexity.

ICON is already known for its innovative 3D-printed homes on Earth, including affordable housing and disaster-resilient structures. Now, the company is adapting its technology for the harsh lunar environment, where extreme temperatures, radiation, and micrometeorite impacts pose unique challenges.

How the Spider-Like Robot Works

The robot, which resembles a mechanical spider, is designed to be mobile and autonomous. It will use a process called additive construction, layering lunar regolith mixed with a binding agent to create durable structures. The robot’s multiple legs provide stability and flexibility, allowing it to navigate uneven terrain and build in various locations.

ICON is collaborating with NASA’s Marshall Space Flight Center and the Moon-to-Mars Planetary Autonomous Construction Technologies (MMPACT) project to refine the robot’s capabilities. The goal is to have a fully functional system ready for deployment by the time NASA’s Artemis program establishes a sustainable human presence on the Moon, potentially as early as the 2030s.

Why 3D Printing is Ideal for Lunar Construction

3D printing offers several advantages for building on the Moon. First, it allows for the use of in-situ resources, reducing the need for costly Earth-based launches. Second, it enables rapid, automated construction, which is essential in an environment where human labor is limited and risky. Third, 3D-printed structures can be designed to withstand lunar conditions, including temperature fluctuations from -280°F to 260°F and high levels of radiation.

ICON’s technology has already been tested in simulated lunar conditions on Earth. The company has built prototype structures using regolith simulants and demonstrated the feasibility of its approach. The next step is to test the system in space-like environments and eventually on the Moon itself.

Applications Beyond the Moon

While the immediate focus is on lunar construction, the implications of this technology extend far beyond. Mars, for example, presents similar challenges in terms of remote construction and resource utilization. A successful lunar 3D printing system could serve as a blueprint for future Martian habitats.

Moreover, the advancements made through Project Olympus could benefit Earth-based construction as well. Techniques developed for space—such as building in remote or hazardous environments—could be adapted for use in disaster zones, military operations, or even sustainable housing in underserved regions.

The Future of Space Architecture

NASA’s investment in ICON underscores a growing recognition that space exploration requires new approaches to infrastructure. Traditional construction methods are impractical in space, and 3D printing offers a scalable, efficient alternative. As the Artemis program progresses, technologies like ICON’s spider-like robot will play a crucial role in enabling long-term human presence beyond Earth.

With continued innovation and collaboration between public and private sectors, the dream of building homes on the Moon—and eventually on Mars—may soon become a reality.

Source: CNN