In a significant leap toward sustainable manufacturing, engineers at MIT have developed a new 3D printing resin derived from plant materials. This innovative resin not only reduces environmental impact but also offers superior mechanical strength compared to conventional petroleum-based resins.

Eco-Friendly 3D Printing Materials

Traditional 3D printing resins are typically made from petrochemicals, which are non-renewable and contribute to environmental degradation. In contrast, the new resin developed by MIT researchers is based on lignin—a natural polymer found in the cell walls of plants. Lignin is a byproduct of the paper and biofuel industries, making it an abundant and underutilized resource.

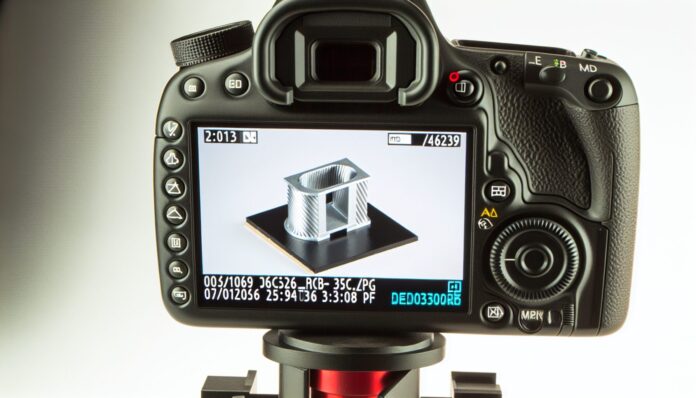

By combining lignin with acrylates (a common component in 3D printing resins), the team created a bio-based resin that can be used in stereolithography (SLA) 3D printers. SLA is a popular 3D printing method that uses light to cure liquid resin into solid objects with high precision.

Stronger and More Sustainable Resin

One of the most impressive aspects of the new resin is its mechanical performance. According to the researchers, the printed parts are up to 60% stronger than those made with standard commercial resins. This makes the material suitable for applications that require high strength and durability, such as automotive components, consumer products, and even aerospace parts.

Moreover, the resin’s plant-based origin significantly reduces its carbon footprint. The team estimates that replacing petroleum-based resins with their lignin-based alternative could cut greenhouse gas emissions associated with 3D printing materials by up to 50%.

How the Resin Works in SLA 3D Printing

The new resin is designed to be compatible with existing SLA 3D printers, which use ultraviolet (UV) light to cure liquid resin layer by layer. The researchers modified the lignin molecules to make them reactive to UV light, allowing them to polymerize and harden during the printing process.

To ensure the resin’s printability and performance, the team conducted extensive testing, including mechanical stress tests and thermal analysis. The results showed that the lignin-based resin not only prints well but also maintains its structural integrity under load and heat.

Applications and Future Potential

This development opens the door to a wide range of sustainable applications in additive manufacturing. Industries that rely on high-performance plastics—such as automotive, aerospace, and consumer electronics—could benefit from switching to this greener alternative.

Additionally, the use of lignin helps address the issue of industrial waste. By valorizing a byproduct that is often discarded or burned, the new resin contributes to a more circular economy. The researchers are now exploring ways to further optimize the resin’s properties and scale up production for commercial use.

As the demand for sustainable materials grows, innovations like MIT’s plant-based resin could play a crucial role in reducing the environmental impact of 3D printing while enhancing the performance of printed parts.

Source: MIT News