In a groundbreaking step toward sustainable construction, a Japanese startup has unveiled the country’s first 3D-printed house made primarily from soil. This innovative project not only challenges traditional building materials like concrete but also opens new possibilities for eco-friendly architecture.

3D Printing with Soil: A Sustainable Alternative

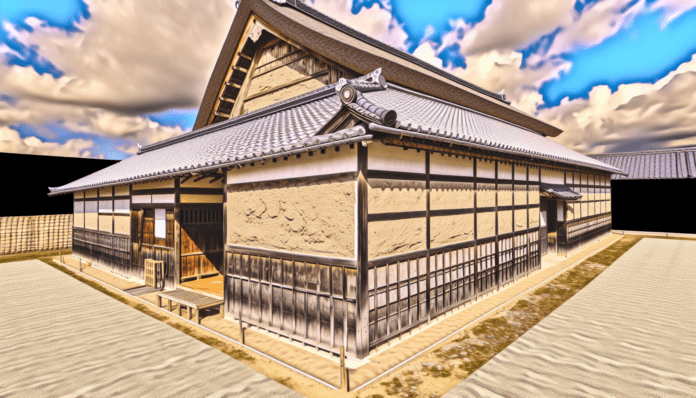

The house, named “Tsuchi”—which means “soil” in Japanese—was developed by Serendix, a startup known for pushing the boundaries of 3D printing in construction. Unlike conventional 3D-printed homes that rely heavily on concrete, Tsuchi is composed of 100% earth-based materials, with 10% of the mix being cement to ensure structural integrity. This approach significantly reduces the carbon footprint associated with traditional building methods.

Serendix collaborated with Hyakunen Jutaku, a Japanese architectural firm, to bring this vision to life. The project was completed in just 23 hours and 12 minutes using a robotic 3D printer, demonstrating the efficiency and scalability of this construction method. The final structure is a dome-shaped home with a floor area of 50 square meters, designed to be both earthquake-resistant and thermally efficient.

Why Soil-Based 3D Printing Matters

Concrete is one of the most widely used construction materials globally, but it comes with a heavy environmental cost. The production of cement, a key ingredient in concrete, accounts for approximately 8% of global CO₂ emissions. By replacing most of the concrete with soil, Serendix’s method offers a more sustainable alternative that could revolutionize the construction industry.

Soil is abundant, locally available, and requires less energy to process compared to cement. Additionally, using soil reduces the need for transporting heavy materials over long distances, further cutting down on emissions. The dome shape of the Tsuchi house also contributes to its sustainability by enhancing structural strength and minimizing material usage.

Technical Details and Construction Process

The Tsuchi house was built using a large-scale robotic arm equipped with a nozzle that extrudes a specially formulated soil mixture. The mixture includes clay, sand, and a small amount of cement to bind the materials together. Layers are printed in a continuous spiral, forming the dome structure without the need for internal supports or scaffolding.

One of the key challenges in using soil for 3D printing is ensuring consistency in the material’s moisture content and composition. Serendix addressed this by developing a proprietary soil blend that maintains uniformity throughout the printing process. The result is a durable, weather-resistant structure that meets Japan’s strict building codes.

In addition to its environmental benefits, the Tsuchi house is also cost-effective. Serendix estimates that the total construction cost is significantly lower than that of a traditional home, making it an attractive option for affordable housing projects.

Applications and Future Potential

The success of the Tsuchi project has far-reaching implications. In regions where access to conventional building materials is limited, soil-based 3D printing could provide a viable solution for constructing homes, schools, and emergency shelters. The technology is also well-suited for disaster recovery efforts, where speed and resource availability are critical.

Serendix plans to continue refining its soil-based 3D printing technology and expand its use in both urban and rural settings. The company envisions a future where sustainable, locally sourced materials become the norm in construction, reducing the industry’s environmental impact while meeting the growing demand for housing.

As the world grapples with climate change and resource scarcity, innovations like the Tsuchi house offer a glimpse into a more sustainable future. By rethinking the materials and methods we use to build, companies like Serendix are paving the way for greener, more resilient communities.

Source: Good News Network