In a major leap forward for additive manufacturing, a team of Israeli scientists has developed a novel method for 3D printing glass using laser technology. This innovation could transform industries ranging from optics to biomedical engineering by enabling the creation of complex, high-precision glass structures that were previously impossible to fabricate.

Laser-Based Glass 3D Printing: A New Frontier

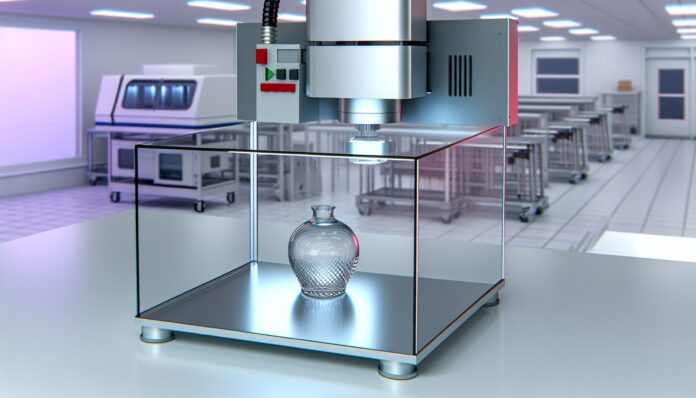

The research, conducted at the Hebrew University of Jerusalem, introduces a technique that uses a focused laser beam to solidify a special resin containing silica nanoparticles. Unlike traditional glass manufacturing, which requires extremely high temperatures and molds, this method allows for the direct creation of intricate glass objects layer by layer at room temperature.

Dr. Michael Layani, one of the lead researchers, explained that the process involves a photopolymer resin loaded with high concentrations of silica. When exposed to a laser, the resin hardens in precise patterns. After printing, the object is heated in a furnace to remove the polymer and fuse the silica particles into transparent glass. This two-step process—printing followed by sintering—results in fully functional glass components with high optical clarity and mechanical strength.

Advantages Over Traditional Glass Manufacturing

Conventional glass shaping methods are limited by the material’s brittleness and the need for high-temperature furnaces and molds. These constraints make it difficult to produce complex geometries or customized parts. The new laser-based 3D printing technique overcomes these limitations by enabling freeform fabrication without the need for molds or subtractive machining.

Moreover, the method offers exceptional resolution, allowing for the creation of micro-scale features. This opens the door to applications in micro-optics, lab-on-a-chip devices, and even custom lenses for medical or scientific instruments. The ability to print glass with such precision and flexibility could also benefit the aerospace and defense sectors, where lightweight, durable, and transparent components are in high demand.

Applications in Optics, Medicine, and Beyond

One of the most promising applications of this technology lies in the field of optics. The researchers demonstrated the ability to print complex optical elements such as lenses and waveguides directly from the resin. These components can be tailored to specific wavelengths and optical properties, making them ideal for use in sensors, imaging systems, and photonic devices.

In the medical field, the technique could be used to produce biocompatible glass implants or microfluidic devices for diagnostics and drug delivery. The precision of the printing process allows for the integration of channels and cavities within the glass, enabling the design of highly functional biomedical tools.

Additionally, the method could revolutionize the production of art and design objects, offering artists and designers a new medium for creative expression. The ability to print glass in complex shapes without molds could lead to entirely new forms of sculpture and architectural elements.

Future Outlook and Industry Impact

While the technology is still in the research phase, its potential has already attracted attention from industry stakeholders. The team is currently working on scaling up the process and improving the speed and efficiency of the printing system. They are also exploring the use of different types of glass and composite materials to expand the range of applications.

This breakthrough aligns with a growing trend in additive manufacturing toward multi-material and functional printing. As the technology matures, it could be integrated into existing 3D printing platforms, making it accessible to a wider range of users and industries.

Ultimately, the ability to 3D print glass with high precision and design freedom could redefine how we think about manufacturing transparent materials. From custom optics to biomedical devices, the possibilities are vast—and this Israeli innovation is leading the way.

Source: The Times of Israel