Researchers at the University of Colorado Boulder have unveiled a groundbreaking open-source software tool designed to simplify and accelerate multi-material 3D printing. This innovation could significantly enhance the capabilities of additive manufacturing by making it easier to print complex objects using multiple materials in a single build.

Advancing Multi-Material 3D Printing

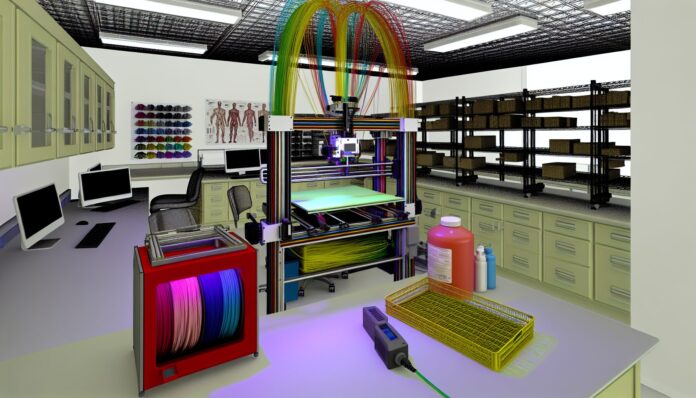

Multi-material 3D printing allows for the creation of objects that combine different physical properties—such as flexibility, rigidity, or conductivity—within a single print. However, the process has traditionally been time-consuming and technically challenging, requiring manual adjustments and complex workflows.

The new software, developed by a team led by Professor Robert MacCurdy of CU Boulder’s College of Engineering and Applied Science, addresses these challenges by automating key steps in the design-to-print pipeline. The tool enables users to assign different materials to specific regions of a 3D model and then automatically generates the necessary toolpaths for multi-material extrusion.

How the Software Works

The software operates by converting standard 3D models into voxel-based representations, where each voxel (a 3D pixel) can be assigned a different material. This voxelization process allows for precise control over material placement, enabling the creation of highly customized and functional parts.

Once the model is voxelized, the software uses a slicing algorithm to generate G-code instructions for multi-material 3D printers. These instructions tell the printer exactly how to deposit each material layer by layer, ensuring accurate transitions and strong inter-material bonding.

Importantly, the software is compatible with open-source hardware and is designed to work with a variety of multi-material 3D printers, including those built by hobbyists and researchers. This flexibility makes it a valuable tool for both academic and industrial users.

Applications and Impact

The ability to easily print with multiple materials opens up new possibilities in fields ranging from soft robotics and wearable electronics to biomedical devices and custom manufacturing. For example, engineers could design a single component that includes both rigid supports and flexible joints, or integrate conductive traces directly into a plastic housing.

By releasing the software as open-source, the CU Boulder team hopes to foster collaboration and innovation within the 3D printing community. The tool is available for download on GitHub, along with documentation and example files to help users get started.

“We want to democratize access to multi-material 3D printing,” said Professor MacCurdy. “By making this software freely available, we’re enabling more people to experiment with and benefit from this powerful technology.”

Background and Future Development

Multi-material 3D printing has been a growing area of research and development over the past decade. While commercial solutions exist, they are often expensive and proprietary, limiting their accessibility. Open-source alternatives like the one developed at CU Boulder help bridge this gap by providing affordable and customizable tools for advanced fabrication.

The team plans to continue improving the software by adding support for more printer types, enhancing the user interface, and integrating simulation tools to predict material behavior. They also encourage feedback and contributions from the community to help refine and expand the platform.

As additive manufacturing continues to evolve, tools like this open-source software will play a crucial role in pushing the boundaries of what’s possible with 3D printing.

Source: University of Colorado Boulder