A team of engineers has unveiled a new 3D printing method that could significantly reduce the cost of titanium parts while improving their strength. This breakthrough could have far-reaching implications for industries like aerospace, automotive, and healthcare, where titanium’s strength-to-weight ratio is critical but its high cost has limited widespread adoption.

New 3D Printing Technique Enhances Titanium Strength

Researchers from the University of Waterloo have developed a novel approach to 3D printing titanium alloys using laser powder bed fusion (LPBF), a common additive manufacturing technique. Their method involves controlling the microstructure of the metal during the printing process to enhance its mechanical properties without the need for costly post-processing steps.

By carefully tuning the printing parameters, such as laser power and scanning speed, the team was able to manipulate how the titanium powder solidified, creating a refined grain structure. This resulted in a printed titanium alloy with significantly improved strength and durability compared to conventionally produced parts.

“We’ve developed a method that not only improves the mechanical performance of additively manufactured titanium but also brings down the cost by eliminating additional heat treatments,” said Professor Mihaela Vlasea, co-author of the study.

Lowering Titanium Manufacturing Costs

Titanium is prized for its corrosion resistance, biocompatibility, and high strength-to-weight ratio, making it ideal for aerospace components, orthopedic implants, and high-performance automotive parts. However, traditional titanium manufacturing is expensive due to the energy-intensive processes required to produce and machine the metal.

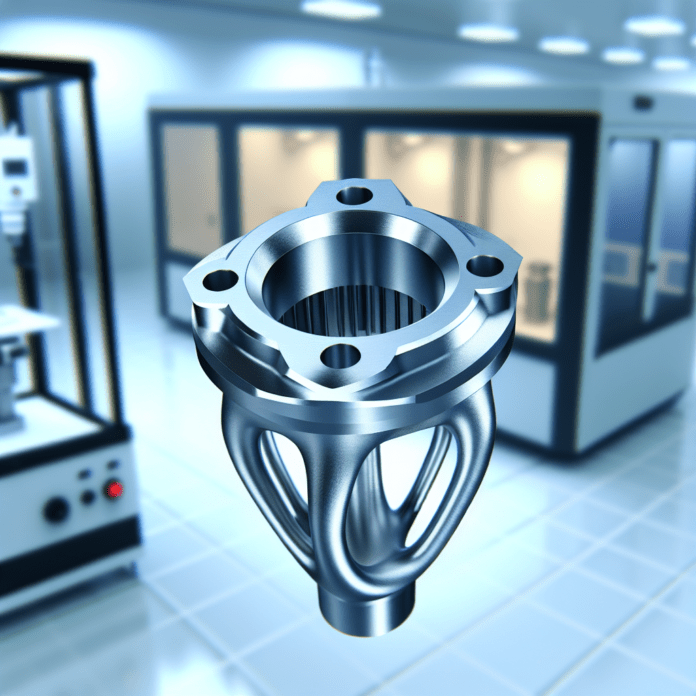

3D printing has offered a promising alternative, allowing for complex geometries and material efficiency. Yet, the mechanical properties of 3D-printed titanium have often lagged behind those of wrought materials, requiring additional processing such as hot isostatic pressing (HIP) to achieve the desired strength.

The new technique developed by the University of Waterloo team overcomes this limitation. It eliminates the need for HIP by directly producing high-strength titanium parts during the printing process. This not only simplifies the manufacturing workflow but also significantly reduces production time and cost.

Implications for Aerospace and Medical 3D Printing

The implications of this advance are substantial. In the aerospace sector, where weight reduction is crucial for fuel efficiency and performance, lightweight and strong titanium components are in high demand. More affordable titanium parts could lead to broader use in both commercial and military aircraft.

In the medical field, titanium is widely used for implants due to its biocompatibility. Reducing production costs could make custom 3D-printed implants more accessible, improving patient outcomes and reducing healthcare expenses. This is especially relevant for orthopedic and dental applications, where patient-specific parts are increasingly common.

The automotive industry could also benefit from this innovation by incorporating stronger, lighter titanium components into high-performance and electric vehicles, improving efficiency and durability.

The Future of Additive Manufacturing with Titanium

This breakthrough highlights the ongoing evolution of additive manufacturing, particularly in the area of metal 3D printing. As researchers continue to refine printing parameters and material science, the performance gap between 3D-printed and traditionally manufactured parts continues to close.

Moreover, this research opens the door for similar advancements in other metal alloys. By applying the same principles to different materials, manufacturers could unlock new efficiencies and capabilities across a range of industries.

The University of Waterloo team’s findings mark a significant step toward making high-performance 3D-printed titanium parts more accessible and cost-effective. As the technology matures, we can expect to see wider adoption and new applications that were previously cost-prohibitive.

Source: SciTechDaily