Carbon, a pioneer in digital manufacturing, has announced a fresh $60 million funding round aimed at accelerating the development and adoption of its proprietary Digital Light Synthesis (DLS) 3D printing technology. This latest investment underscores the growing confidence in Carbon’s vision to revolutionize additive manufacturing for mass production.

Carbon’s DLS Technology: A Game-Changer in 3D Printing

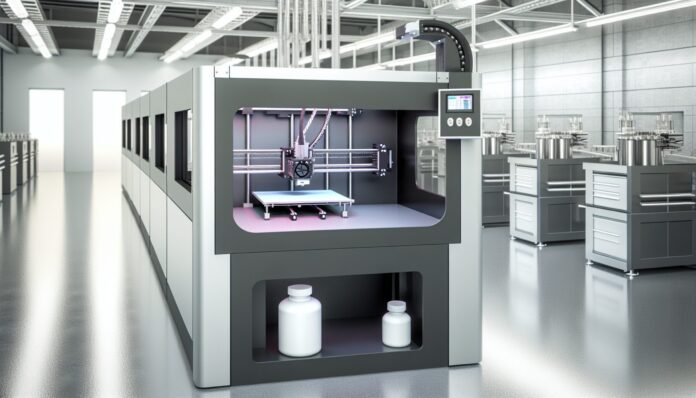

Carbon’s Digital Light Synthesis (DLS) technology stands out in the 3D printing landscape for its ability to produce high-resolution, end-use parts with exceptional mechanical properties. Unlike traditional layer-by-layer additive manufacturing methods, DLS uses a photochemical process that harnesses light and oxygen to cure liquid resin into solid parts. This continuous printing process enables faster production speeds and superior surface finishes, making it ideal for applications in industries such as automotive, healthcare, and consumer goods.

Since its inception, Carbon has focused on bridging the gap between prototyping and production. Its DLS technology has already been adopted by major brands like Adidas, Riddell, and Ford, demonstrating its potential for scalable, real-world manufacturing. The company’s platform includes not only hardware but also advanced software and a growing library of high-performance materials.

$60 Million Funding to Drive Innovation and Growth

The $60 million investment was led by new and existing investors, including Hydra Ventures, ARCHINA Capital, and Baillie Gifford. According to Carbon, the funds will be used to further develop its next-generation M-series printers, expand its materials portfolio, and enhance its software capabilities. The company also plans to scale its global operations and strengthen its partnerships with manufacturers across various sectors.

Phil DeSimone, CEO of Carbon, emphasized the importance of this funding in supporting the company’s mission to transform manufacturing. “This investment enables us to continue pushing the boundaries of what’s possible with 3D printing,” he said. “We’re committed to delivering innovative solutions that help our customers bring better products to market faster.”

Expanding Applications Across Industries

Carbon’s technology is already making waves in several key industries. In the medical field, DLS is used to produce custom dental aligners, surgical instruments, and prosthetics with precise geometries and biocompatible materials. In the automotive sector, manufacturers leverage Carbon’s printers to create lightweight, durable components for both prototyping and end-use applications.

One of the most notable success stories is Carbon’s collaboration with Adidas to produce the Futurecraft 4D midsole. Using DLS, Adidas was able to design and manufacture a lattice structure that offers superior cushioning and performance. This partnership marked one of the first large-scale uses of 3D printing in consumer footwear and set a precedent for future applications.

Carbon’s materials portfolio includes a wide range of resins tailored for specific use cases, such as rigid, flexible, and high-temperature materials. The company continues to invest in R&D to develop new materials that meet the evolving needs of its customers.

The Future of Digital Manufacturing

With this new funding, Carbon is well-positioned to lead the next phase of digital manufacturing. The company’s integrated approach—combining hardware, software, and materials—offers a comprehensive solution for companies looking to transition from traditional manufacturing to agile, on-demand production.

As the demand for customized, high-performance products grows, Carbon’s DLS technology provides a scalable and cost-effective alternative to injection molding and other conventional methods. The company’s focus on sustainability, speed, and quality aligns with the broader trends shaping the future of manufacturing.

In a rapidly evolving industry, Carbon’s continued innovation and strategic investments signal a strong commitment to redefining how products are designed, engineered, and produced.

Source: 3DPrint.com