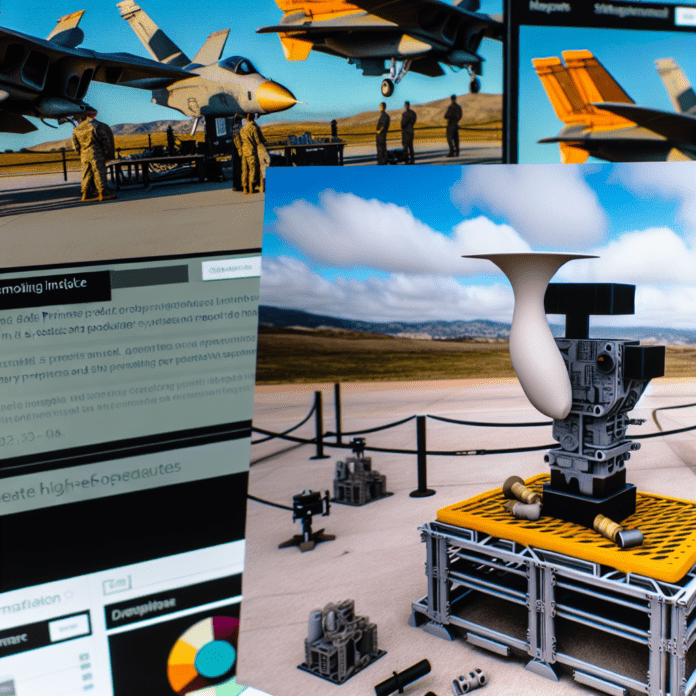

In San Diego, a cutting-edge partnership between artificial intelligence and 3D printing is helping the U.S. military solve a long-standing problem: the slow turnaround time for repairing critical parts. What once took months can now be completed in just days, thanks to advanced additive manufacturing and digital design tools.

How 3D Printing Is Transforming Military Logistics

Traditionally, when a part on a military ship or aircraft broke, the replacement process was time-consuming and expensive. The part might no longer be in production, or it could take weeks to arrive from a distant supplier. But at the Naval Information Warfare Center (NIWC) Pacific in San Diego, engineers are turning to 3D printing to create replacement parts on demand.

Using high-performance 3D printers, the team can fabricate components in-house, drastically reducing both costs and shipping delays. These printers are capable of working with a variety of materials, including high-strength polymers and metals, allowing them to create durable parts that meet stringent military specifications.

AI-Powered Design for Faster Prototyping

What sets this initiative apart is the integration of artificial intelligence. Engineers use AI algorithms to reverse-engineer broken or outdated parts. By scanning the original component and feeding the data into AI-powered modeling software, they can quickly generate a digital blueprint for 3D printing. This process, known as generative design, allows for rapid prototyping and even performance improvements over the original part.

“We’re not just recreating parts—we’re optimizing them,” said a NIWC Pacific engineer. The AI helps identify weaknesses in the original design and suggests improvements that can extend the part’s lifespan or reduce its weight without compromising strength.

Proven Success: Real-World Applications

The program has already proven its worth. In one case, a key component for a Navy vessel’s communication system failed. Normally, the replacement would have taken up to six months to arrive. Instead, the NIWC team reverse-engineered and 3D printed the part in under a week. The ship returned to service without significant delay.

Other applications include brackets, housings, and even custom tools tailored to specific maintenance tasks. Each successful print not only saves time but also ensures that operational readiness is maintained across the fleet.

The Future of Military Additive Manufacturing

This fusion of AI and 3D printing is part of a broader Department of Defense initiative to modernize its logistics and maintenance networks. As additive manufacturing becomes more advanced and portable, the military envisions deploying mobile 3D printing units directly to ships or forward operating bases. This would allow for on-site fabrication of critical parts, reducing reliance on global supply chains.

Moreover, the Navy is investing in training programs to ensure that service members are equipped with the skills to operate 3D printers and AI design tools. By building this capability into its workforce, the military aims to become more agile and self-sufficient in the face of future challenges.

Source: fox5sandiego.com