Airbus is taking a significant leap forward in aerospace manufacturing by integrating titanium 3D printing into its production processes. This move not only enhances the performance of aircraft components but also streamlines manufacturing and reduces material waste.

Airbus Embraces Titanium 3D Printing for Aircraft Components

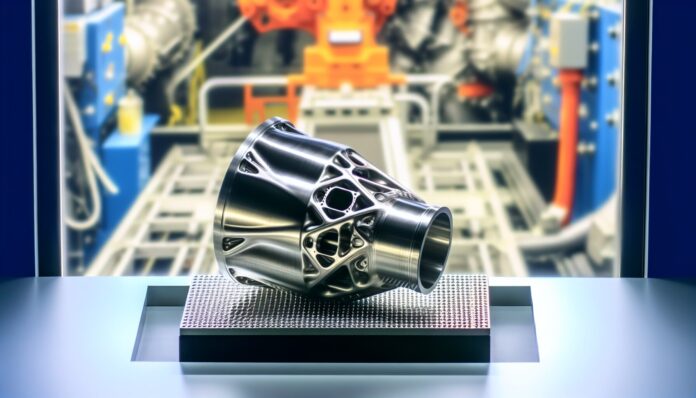

In a bid to optimize aircraft performance and production efficiency, Airbus has begun using titanium 3D printing to fabricate structural parts for its commercial aircraft. Titanium, known for its high strength-to-weight ratio and corrosion resistance, is an ideal material for aerospace applications. By leveraging additive manufacturing, Airbus can produce complex geometries that are difficult or impossible to achieve with traditional subtractive methods.

One of the key advantages of 3D printing in aerospace is the ability to consolidate multiple parts into a single, lightweight component. This not only reduces the overall weight of the aircraft—leading to improved fuel efficiency—but also simplifies assembly and maintenance. Airbus has already implemented 3D-printed titanium parts in several aircraft models, including the A350 XWB, where brackets and structural supports have been additively manufactured.

Benefits of Additive Manufacturing in Aerospace

The adoption of 3D printing in aerospace offers numerous benefits beyond weight reduction. Additive manufacturing allows for rapid prototyping and faster iteration cycles, enabling engineers to test and refine designs more quickly. This accelerates the development process and shortens time-to-market for new aircraft models.

Moreover, 3D printing significantly reduces material waste. Traditional machining methods often involve cutting away large amounts of material from a solid block, whereas additive manufacturing builds parts layer by layer, using only the material necessary. This not only lowers material costs but also aligns with Airbus’s sustainability goals by minimizing environmental impact.

Another critical advantage is supply chain resilience. By producing parts on-demand and closer to the point of use, Airbus can reduce its reliance on complex global supply chains. This flexibility proved especially valuable during the COVID-19 pandemic, when traditional manufacturing and logistics were severely disrupted.

Technical Challenges and Innovations

While the benefits of titanium 3D printing are clear, the technology also presents unique challenges. Titanium is notoriously difficult to work with due to its high melting point and reactivity with oxygen. To overcome these hurdles, Airbus collaborates with leading additive manufacturing companies and research institutions to develop advanced printing techniques and post-processing methods.

One such innovation is the use of electron beam melting (EBM) and selective laser melting (SLM) technologies, which are particularly well-suited for printing titanium alloys. These processes occur in vacuum or inert gas environments to prevent oxidation and ensure high-quality parts. Additionally, Airbus employs rigorous quality control measures, including non-destructive testing and in-situ monitoring, to ensure that 3D-printed components meet stringent aerospace standards.

Airbus is also investing in digital design tools and simulation software to optimize part geometries for additive manufacturing. Topology optimization, for example, allows engineers to design parts that use the least amount of material while maintaining structural integrity. This results in components that are not only lighter but also more efficient and cost-effective to produce.

Future Outlook: Scaling Up 3D Printing in Aerospace

Looking ahead, Airbus plans to expand its use of 3D printing across more aircraft platforms and component types. The company is exploring the potential of printing larger and more complex parts, including entire fuselage sections and engine components. To support this vision, Airbus is scaling up its additive manufacturing capabilities by investing in new facilities, equipment, and workforce training.

In parallel, Airbus is working with regulatory bodies to establish certification standards for 3D-printed aerospace parts. Ensuring compliance with safety and performance requirements is essential for the widespread adoption of additive manufacturing in commercial aviation.

As the technology matures, Airbus envisions a future where digital manufacturing plays a central role in aircraft production. By combining 3D printing with other Industry 4.0 technologies—such as artificial intelligence, robotics, and digital twins—the company aims to create a more agile, efficient, and sustainable manufacturing ecosystem.

In summary, Airbus’s adoption of titanium 3D printing marks a transformative step in aerospace manufacturing. By embracing additive technologies, the company is not only enhancing the performance and efficiency of its aircraft but also paving the way for a more innovative and resilient aviation industry.

Source: Airbus