In a breakthrough that could reshape the future of soft robotics and biomedical devices, researchers have developed 3D-printed hydrogel microactuators that mimic the motion of natural cilia. These tiny, hair-like structures are capable of programmable, low-voltage-driven movement, opening new possibilities for responsive, flexible systems in medicine and engineering.

3D Printing Meets Bioinspired Design

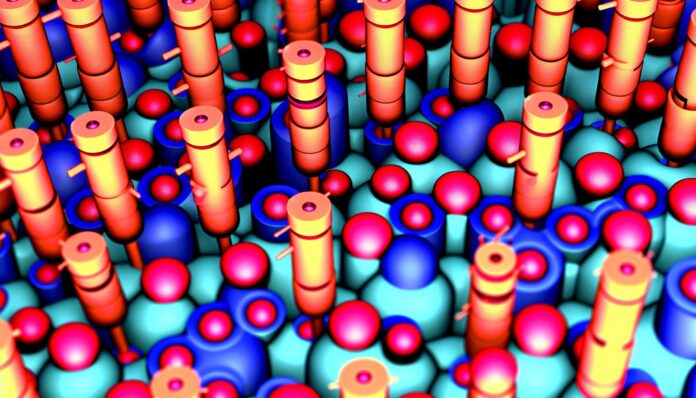

The research, published in Nature, showcases a novel approach to fabricating microactuators using digital light processing (DLP) 3D printing. The team, led by scientists from the Max Planck Institute for Intelligent Systems and the University of Stuttgart, engineered a hydrogel-based material that can be printed into complex, cilia-like structures. These structures are capable of bending and moving in response to low-voltage electrical stimulation.

Natural cilia are microscopic, hair-like projections found on the surface of cells, playing crucial roles in locomotion, fluid transport, and sensory functions. Mimicking their function in synthetic systems has long been a goal in soft robotics, but achieving precise, programmable motion at such a small scale has proven difficult—until now.

How the Hydrogel Microactuators Work

The key to the innovation lies in the hydrogel’s composition and the 3D printing process. The hydrogel is infused with ionic components that respond to electric fields. When a low voltage is applied, the ions redistribute within the gel, causing it to swell or contract in specific regions. This results in controlled bending or waving motions, much like natural cilia.

Using DLP 3D printing, the researchers were able to fabricate arrays of these microactuators with high precision. The printing process allows for the creation of complex geometries and spatially varying material properties, enabling the design of actuators with customized motion profiles. The actuators can be programmed to move in coordinated patterns, making them ideal for applications that require synchronized motion, such as fluid pumping or locomotion in soft robots.

Applications in Soft Robotics and Biomedicine

This technology has far-reaching implications. In soft robotics, these microactuators could be used to create flexible, responsive surfaces that move or change shape on demand. For example, they could be integrated into robotic skins that adapt to their environment or into soft grippers that conform to delicate objects.

In biomedical applications, the actuators could be used to mimic biological processes, such as moving fluids through microchannels or assisting in tissue engineering. Because the hydrogel is biocompatible and operates at low voltages, it is well-suited for use in or near the human body. Potential future uses include implantable devices that respond to electrical signals or smart bandages that actively promote healing.

Challenges and Future Directions

While the results are promising, there are still challenges to overcome. The durability and long-term stability of the hydrogel actuators need further testing, especially in biological environments. Additionally, scaling up the technology for larger systems or mass production will require further development of the printing and material formulation processes.

Nevertheless, this research represents a significant step forward in the integration of 3D printing and soft robotics. By combining bioinspired design with advanced manufacturing techniques, the team has opened new avenues for creating responsive, programmable systems at the microscale.

As the field of soft robotics continues to grow, innovations like these hydrogel microactuators will play a crucial role in developing the next generation of adaptive, intelligent machines.

Source: Nature