As the 3D printing industry continues to evolve, 2026 is shaping up to be a pivotal year for innovation and growth. From smarter software to sustainable materials, the additive manufacturing landscape is undergoing a transformation that will impact industries from aerospace to healthcare.

AI and Automation in 3D Printing

Artificial intelligence is becoming a cornerstone of modern 3D printing workflows. In 2026, expect to see AI-driven design tools that optimize part geometry for performance and material efficiency. Machine learning algorithms are also being used to predict print failures, adjust parameters in real-time, and streamline post-processing. This level of automation not only reduces human error but also accelerates production timelines, making additive manufacturing more viable for mass production.

Companies like Autodesk and Siemens are leading the charge with generative design platforms that integrate seamlessly with 3D printers. These tools allow engineers to input performance requirements and receive optimized designs that would be impossible to create manually. As AI continues to mature, its role in additive manufacturing will only deepen, enabling smarter, faster, and more cost-effective production.

Sustainable Materials and Circular Manufacturing

Environmental concerns are pushing the 3D printing industry toward greener practices. In 2026, sustainable materials such as recycled polymers, bio-based resins, and metal powders derived from scrap will become more mainstream. Companies are also exploring closed-loop systems where waste material is reprocessed and reused, reducing the environmental footprint of additive manufacturing.

For example, startups like Reflow and Filabot are developing filament made from recycled plastic waste, while large manufacturers are investing in powder recovery systems for metal 3D printing. These innovations not only support sustainability goals but also lower material costs, making 3D printing more accessible to a wider range of users.

Industrial-Scale Additive Manufacturing

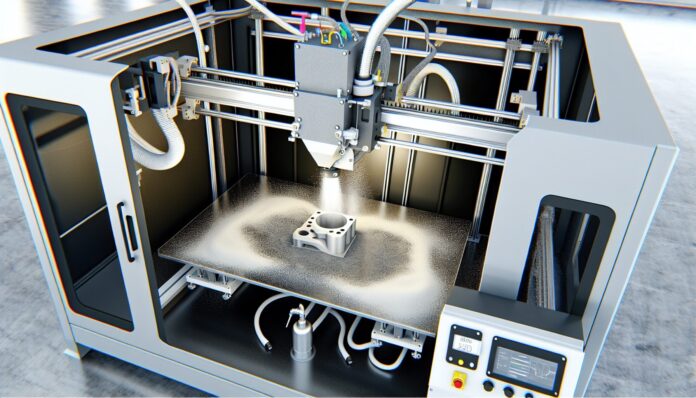

One of the most significant trends for 2026 is the scaling of 3D printing for industrial production. Technologies like binder jetting, directed energy deposition (DED), and multi-laser powder bed fusion are enabling faster build rates and larger part sizes. This shift is particularly evident in sectors like aerospace, automotive, and energy, where complex, high-performance parts are in demand.

Companies such as GE Additive, HP, and Desktop Metal are investing heavily in production-grade systems that can operate 24/7 with minimal downtime. These machines are designed for factory integration, with features like automated part removal, in-line quality control, and digital twin capabilities. As a result, additive manufacturing is moving from prototyping to full-scale production, offering new opportunities for supply chain resilience and on-demand manufacturing.

Advancements in Bioprinting and Healthcare Applications

Bioprinting is another area poised for major breakthroughs in 2026. Researchers are making strides in printing functional tissues, including skin, cartilage, and even organ scaffolds. While fully functional 3D-printed organs are still years away, the progress being made is laying the groundwork for future medical applications.

In addition to bioprinting, 3D printing is being used to create custom implants, prosthetics, and surgical guides. These applications are improving patient outcomes by offering personalized solutions that fit the unique anatomy of each individual. With regulatory bodies becoming more familiar with additive manufacturing, the path to clinical adoption is becoming clearer.

Software and Workflow Integration

As 3D printing becomes more complex, the need for integrated software solutions is growing. In 2026, expect to see more end-to-end platforms that connect design, simulation, printing, and post-processing. These systems will offer real-time monitoring, predictive maintenance, and data analytics to optimize every stage of the production process.

Cloud-based platforms are also gaining traction, enabling remote collaboration and centralized control of distributed manufacturing networks. This is particularly valuable for companies operating across multiple sites or working with external partners. By streamlining workflows and improving traceability, integrated software solutions are making additive manufacturing more scalable and reliable.

Conclusion

The 3D printing industry is entering a new era of innovation, driven by advancements in AI, sustainability, industrial scalability, and healthcare applications. As we look ahead to 2026, these trends will redefine what’s possible with additive manufacturing, opening up new opportunities across a wide range of industries.

Source: 3DPrint.com