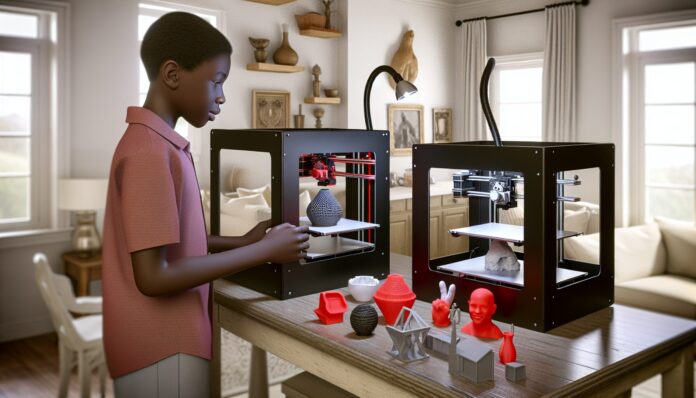

In a quiet neighborhood in Eugene, Oregon, the hum of 3D printers fills the home of 11-year-old entrepreneur, Aiden Johnson. While most kids his age are focused on school and video games, Aiden is running a full-fledged 3D printing business from his family’s living room, with 11 printers working around the clock.

Young Entrepreneur Builds 3D Printing Business

Aiden’s journey into 3D printing began during the COVID-19 pandemic when he received his first printer as a gift. What started as a hobby quickly evolved into a business opportunity. Fascinated by the technology, Aiden taught himself how to design and print a variety of objects, from fidget toys to custom keychains. He now sells his creations through an online storefront and at local markets.

His parents, both supportive and amazed, helped him set up a dedicated workspace in their home. The business, which he named Aiden’s Printing Press, has grown steadily thanks to word-of-mouth, social media, and a strong presence on platforms like Etsy. Aiden reinvests his earnings into new materials and additional printers, expanding his capabilities and product range.

3D Printing at Home: Tools and Techniques

Aiden currently operates 11 FDM (Fused Deposition Modeling) 3D printers, a popular and accessible type of printer that uses thermoplastic filament to build objects layer by layer. He primarily uses PLA (Polylactic Acid) filament, a biodegradable and user-friendly material ideal for beginners and small-scale production.

To manage his growing operation, Aiden uses slicing software like Cura to prepare his 3D models for printing. He also designs some of his own models using Tinkercad, a beginner-friendly CAD tool. For more complex designs, he occasionally turns to Fusion 360. His workflow includes regular maintenance of the printers, troubleshooting print errors, and packaging orders for shipment.

Inspiring the Next Generation of Makers

Aiden’s story is more than just a tale of youthful ambition—it’s a testament to the accessibility and potential of 3D printing technology. With relatively low startup costs and a wealth of free online resources, young makers like Aiden can turn their creativity into real-world products and even profitable businesses.

His success has inspired classmates and community members alike. Aiden has given presentations at his school and local maker events, encouraging other kids to explore STEM fields and hands-on learning. His parents say the experience has taught him valuable lessons in entrepreneurship, time management, and customer service.

The Future of 3D Printing and Youth Innovation

As 3D printing continues to evolve, stories like Aiden’s highlight the growing role of young innovators in shaping the future of manufacturing. With advancements in materials, printer capabilities, and design software, the barriers to entry are lower than ever. Educational institutions and community makerspaces are increasingly incorporating 3D printing into their programs, further fueling interest among students.

For Aiden, the journey is just beginning. He hopes to expand his business, learn more advanced design techniques, and eventually create his own line of original products. His story serves as a powerful reminder that age is no barrier to innovation—and that with the right tools and support, anyone can become a maker.

Source: The Register-Guard