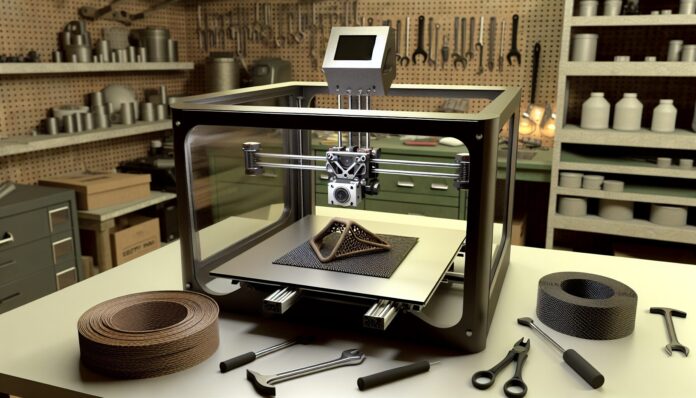

Desktop 3D printing has come a long way from its early days of plastic trinkets and prototypes. Now, a new entrant in the enthusiast market is pushing the boundaries of what’s possible at home or in small workshops. The Anvil printer, developed by Anvil Print, is designed to bring industrial-grade strength to desktop 3D printing by incorporating continuous carbon fiber into its prints.

Continuous Carbon Fiber 3D Printing: A Game Changer

Unlike traditional FDM (Fused Deposition Modeling) printers that use thermoplastics like PLA or ABS, the Anvil printer integrates continuous carbon fiber into its prints. This method dramatically increases the strength-to-weight ratio of printed parts, making them suitable for demanding applications such as automotive components, drone frames, and even structural parts in robotics.

Continuous fiber reinforcement is not new in the industrial space—companies like Markforged have been offering this technology for years. However, Anvil Print aims to make it accessible to hobbyists, engineers, and small businesses by offering a more affordable and user-friendly solution.

How the Anvil Printer Works

The Anvil printer uses a dual-extrusion system. One nozzle deposits a standard thermoplastic filament, while the second nozzle lays down continuous strands of carbon fiber. The carbon fiber is embedded directly into the part during the printing process, following the toolpath to reinforce areas that require additional strength.

This approach differs from chopped carbon fiber filaments, which mix short carbon fibers into the plastic. While chopped fiber filaments offer improved stiffness, they don’t come close to the mechanical properties of continuous fiber reinforcement. Anvil’s system allows users to specify where and how the carbon fiber is laid, giving them control over the strength and weight distribution of the final part.

Targeting Enthusiasts and Professionals Alike

One of the most compelling aspects of the Anvil printer is its accessibility. While industrial continuous fiber printers can cost tens of thousands of dollars, Anvil Print is targeting a price point that puts this technology within reach of serious hobbyists and small businesses. The company has not yet announced a final retail price, but early indications suggest it will be significantly more affordable than existing solutions.

In addition to hardware, Anvil Print is developing a custom slicer that simplifies the process of adding carbon fiber reinforcement. Users can select regions of a part to reinforce, and the software automatically generates the necessary toolpaths. This user-friendly approach lowers the barrier to entry for those unfamiliar with composite manufacturing techniques.

Applications and Future Potential

The ability to print strong, lightweight parts opens up a wide range of applications. In the automotive industry, for example, engineers can prototype and even produce end-use parts that withstand mechanical stress. Drone enthusiasts can build frames that are both light and durable. Makers and inventors can create functional prototypes that perform like final products.

As the technology matures, we may see even broader adoption in fields like aerospace, sports equipment, and medical devices. The key will be maintaining affordability and ease of use while continuing to improve material properties and software capabilities.

With the Anvil printer, Anvil Print is taking a bold step toward democratizing high-performance 3D printing. By bringing continuous carbon fiber reinforcement to the desktop, they’re enabling a new generation of makers to build stronger, lighter, and more functional parts than ever before.

Source: New Atlas