Researchers have unveiled a groundbreaking laser-assisted 3D printing technique that can fabricate free-standing thermoset-based electronics in mere seconds. This innovation could significantly accelerate the production of complex electronic components, offering new possibilities for rapid prototyping and on-demand manufacturing.

Laser-Assisted 3D Printing: A Game Changer for Thermoset Electronics

Thermoset polymers are widely used in electronics due to their excellent mechanical strength, thermal stability, and chemical resistance. However, their use in additive manufacturing has been limited because they require high temperatures and long curing times. Traditional 3D printing methods struggle to process thermosets efficiently, especially when creating intricate or free-standing structures.

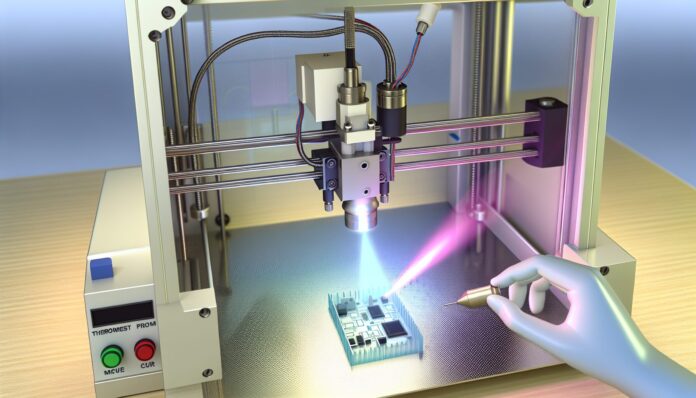

To overcome these challenges, a team of researchers from the Singapore University of Technology and Design (SUTD) developed a novel laser-assisted direct ink writing (LDIW) technique. This method uses a focused laser beam to rapidly cure a specially formulated thermoset resin as it is extruded from a nozzle. The result is a solid, free-standing structure that forms almost instantly, eliminating the need for post-processing or extended curing times.

How the Technology Works

The LDIW process combines a custom-formulated thermoset ink with a near-infrared (NIR) laser. The ink contains a photothermal agent that absorbs the laser’s energy and converts it into heat, triggering the curing reaction. As the ink is deposited layer by layer, the laser follows the nozzle path, curing the material in real time. This allows for the creation of complex geometries and overhangs without the need for support structures.

One of the key innovations is the use of carbon black nanoparticles as the photothermal agent. These particles efficiently absorb NIR light and generate localized heat, enabling rapid curing without damaging the surrounding material. The researchers demonstrated that their method could produce structures with high resolution and mechanical integrity in just seconds.

Applications in Electronics and Beyond

This breakthrough has significant implications for the electronics industry. The ability to print thermoset-based components quickly and accurately opens the door to new applications in wearable electronics, flexible circuits, and customized sensors. The technique could also be used to fabricate microelectromechanical systems (MEMS), antennas, and other high-performance devices that require precise material properties.

Beyond electronics, the LDIW method could be adapted for use in aerospace, automotive, and biomedical fields, where thermoset materials are valued for their durability and resistance to harsh environments. The speed and precision of the process make it ideal for rapid prototyping and small-batch production, reducing time-to-market and development costs.

Future Outlook and Research Directions

While the current study focused on a specific thermoset formulation, the researchers believe the technique can be extended to other materials by adjusting the ink composition and laser parameters. Future work will explore the integration of conductive fillers to create fully functional electronic circuits and the development of multi-material printing capabilities.

The team also plans to investigate the scalability of the process for industrial applications. By optimizing the laser system and printing hardware, they aim to increase throughput and enable the production of larger components. With continued research and development, laser-assisted 3D printing could become a standard tool for fabricating advanced thermoset-based devices.

Source: Tech Xplore