A new Czech–Israeli technology partnership is making waves in the global 3D printing industry, aiming to disrupt China’s stronghold on additive manufacturing. By combining advanced hardware and secure software, this alliance is offering a powerful alternative to Chinese-made 3D printers, with a focus on scalability, cybersecurity, and industrial-grade performance.

Strategic Partnership in 3D Printing Innovation

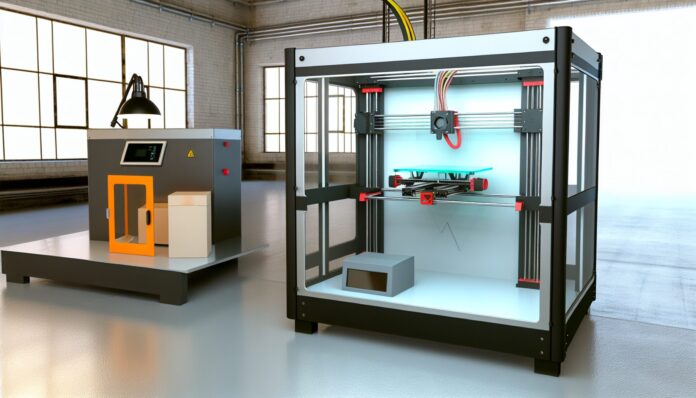

The collaboration brings together Czech company TRILAB, known for its high-performance delta 3D printers, and Israeli software firm Nexa3D, which specializes in secure, cloud-based 3D printing platforms. Together, they are developing a new generation of 3D printers that not only deliver precision and speed but also address growing concerns over cybersecurity and supply chain reliability.

TRILAB’s delta printers are already recognized for their unique kinematic design, which allows for faster and more accurate printing, especially for tall and complex parts. Nexa3D contributes its expertise in secure software infrastructure, ensuring that the printers can be safely integrated into industrial and defense environments without the risk of data breaches or foreign interference.

Challenging China’s Market Dominance

China currently dominates the global 3D printing hardware market, particularly in the consumer and entry-level industrial segments. However, concerns over intellectual property theft, data security, and geopolitical tensions have prompted many Western companies and governments to seek alternatives.

The Czech–Israeli alliance positions itself as a trustworthy and technologically advanced option. By manufacturing in Europe and Israel, the partnership ensures compliance with Western cybersecurity standards and export regulations. This is particularly appealing to defense contractors, aerospace firms, and other sensitive industries that require secure and reliable additive manufacturing solutions.

Applications Across Defense, Aerospace, and Industry

The new 3D printing systems developed by TRILAB and Nexa3D are designed for a wide range of applications. In the defense sector, they can be used to produce mission-critical components on demand, reducing reliance on foreign suppliers and improving operational readiness. In aerospace, the printers offer the precision and material compatibility needed for lightweight, high-performance parts.

Industrial users benefit from the printers’ scalability and ease of integration into existing production lines. The software platform supports remote monitoring, automated workflows, and secure data handling, making it suitable for Industry 4.0 environments. Additionally, the printers are compatible with a variety of engineering-grade materials, including high-temperature polymers and composites.

Looking Ahead: A Secure Future for Additive Manufacturing

As the global demand for additive manufacturing continues to grow, the need for secure, scalable, and high-performance 3D printing solutions becomes increasingly urgent. The Czech–Israeli partnership is not only addressing these needs but also setting a new standard for what industrial 3D printing can achieve.

By offering an alternative to Chinese-made systems, this alliance is helping to diversify the global supply chain and reduce strategic dependencies. It also highlights the importance of international collaboration in driving innovation and ensuring technological sovereignty in critical sectors.

With continued investment and development, the Czech–Israeli 3D printing platform could become a cornerstone of secure additive manufacturing in Europe, the Middle East, and beyond.

Source: The Jerusalem Post