In a remarkable display of DIY ingenuity, a maker has successfully built a fully functional 3D printed camera using the sensor from an optical mouse. While the resulting images are low-resolution, the project showcases the potential of combining 3D printing with repurposed electronics to create unique, working devices.

3D Printing Meets DIY Electronics

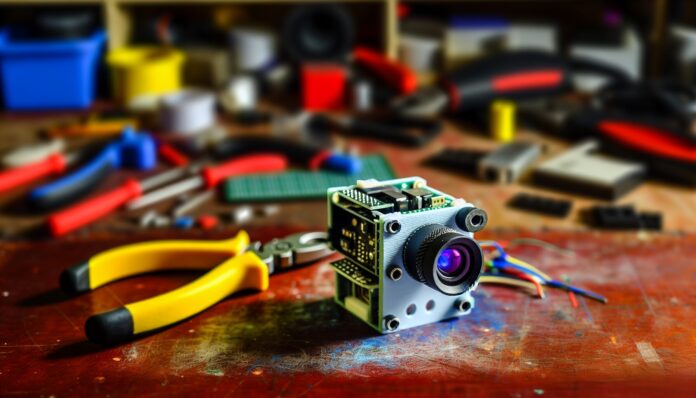

The project, shared by a maker known as ‘abzman2’ on Hackaday, involved repurposing the sensor from a Logitech M187 optical mouse to serve as the image sensor for a custom-built camera. The entire camera body was 3D printed, and the electronics were carefully integrated to allow the device to capture images at a resolution of 30×30 pixels.

While this resolution may seem minuscule by modern standards, the achievement lies in the creative reuse of everyday components and the precision required to make them work together. The camera is not just a static model—it actually takes photos, albeit in a lo-fi, pixelated format reminiscent of early digital imaging.

How the Optical Mouse Sensor Works in a Camera

Optical mouse sensors are designed to detect movement by capturing thousands of images per second of the surface beneath them. These sensors typically have low resolution but high frame rates, making them ideal for tracking motion rather than capturing detailed images. However, with some clever engineering, abzman2 was able to adapt the sensor to function as a basic image capture device.

The sensor used in this project is capable of capturing grayscale images at 30×30 pixels. To build the camera, the maker had to design a custom PCB, write firmware to interface with the sensor, and develop software to process and display the images. The camera also includes a simple lens system to focus light onto the sensor, all housed within a 3D printed enclosure.

Challenges and Build Time

According to the maker, the entire project took around 65 hours to complete. This includes time spent designing the 3D printed parts, assembling the electronics, writing code, and troubleshooting. One of the biggest challenges was aligning the lens and sensor correctly to ensure that the captured images were in focus and properly exposed.

Another hurdle was dealing with the limited capabilities of the mouse sensor. Since it was never intended for photography, the sensor required significant adaptation to function in this new role. The maker had to experiment with different lighting conditions and exposure times to get usable images.

Applications and Educational Value

While the camera is not practical for everyday photography, it serves as an excellent educational tool. Projects like this demonstrate the principles of digital imaging, optics, and embedded systems in a hands-on, accessible way. It also highlights the versatility of 3D printing in prototyping and custom hardware development.

For hobbyists, educators, and students, this project offers inspiration to explore the intersection of 3D printing and electronics. It shows that with creativity and persistence, even the most unlikely components—like a mouse sensor—can be transformed into something entirely new.

Source: Tom’s Hardware