Researchers have developed a groundbreaking 3D printing technique that allows for the fabrication of miniaturized infrared (IR) sensors at room temperature. This innovation could significantly impact the design and production of compact, low-cost sensors for a wide range of applications, from wearable electronics to environmental monitoring.

Room-Temperature 3D Printing: A Game Changer for Sensor Fabrication

Traditional methods for manufacturing infrared sensors often require high-temperature processing, cleanroom environments, and complex fabrication steps. These constraints limit the scalability and affordability of IR sensor production. However, a team of scientists from the University of California, San Diego, has introduced a novel room-temperature 3D printing process that overcomes these limitations.

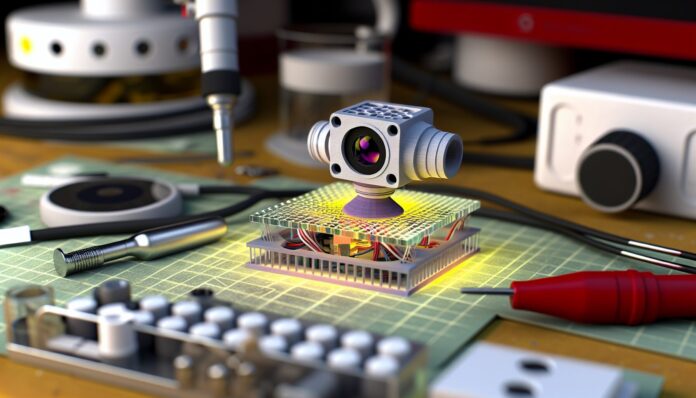

The technique involves a direct-ink-writing (DIW) method that prints a functional IR-sensing material onto a substrate without the need for post-processing or high-temperature sintering. The printed material is a composite of tellurium nanowires and a polymer binder, which together form a photoconductive layer sensitive to infrared light.

This approach enables the creation of highly miniaturized IR sensors with customizable geometries, making it ideal for integration into compact electronic devices. Moreover, the room-temperature process allows for printing on flexible or heat-sensitive substrates, expanding the range of potential applications.

How the 3D-Printed IR Sensors Work

The core of the sensor is a photoconductive material that changes its electrical resistance in response to infrared radiation. When IR light hits the sensor, it excites electrons in the tellurium nanowires, increasing the material’s conductivity. This change can be measured and used to detect the presence and intensity of IR radiation.

In the researchers’ prototype, the sensor was printed directly onto a glass substrate using a nozzle-based DIW printer. The resulting device demonstrated a fast response time and high sensitivity to IR light in the mid-infrared range (3–5 micrometers), which is commonly used in thermal imaging and gas sensing.

One of the key advantages of this method is its simplicity. The entire sensor can be printed in a single step, without the need for complex lithography or etching processes. This not only reduces manufacturing costs but also makes the technology accessible to a wider range of users, including small-scale manufacturers and research labs.

Applications in Wearables, IoT, and Environmental Monitoring

The ability to 3D print IR sensors at room temperature opens up exciting possibilities for integrating these devices into everyday technologies. For example, wearable health monitors could use IR sensors to track body temperature or detect inflammation. Smart home devices could incorporate them for motion detection or energy-efficient climate control.

In the field of environmental monitoring, miniaturized IR sensors could be deployed in remote or hard-to-reach locations to detect gas leaks, monitor air quality, or track temperature changes. Their small size and low power requirements make them ideal for use in Internet of Things (IoT) networks, where sensors must operate autonomously for extended periods.

Additionally, the flexibility of the 3D printing process allows for rapid prototyping and customization. Engineers can quickly iterate on sensor designs to suit specific applications, reducing development time and accelerating innovation.

Future Outlook and Research Directions

While the current prototype demonstrates promising performance, the researchers are continuing to refine the materials and printing process to improve sensitivity, durability, and scalability. Future work may explore the use of alternative nanomaterials, multi-material printing, and integration with other electronic components.

This room-temperature 3D printing technique represents a significant step forward in the field of additive manufacturing and sensor technology. By simplifying the fabrication of IR sensors and enabling new form factors, it paves the way for smarter, more responsive devices across a wide range of industries.

Source: Phys.org