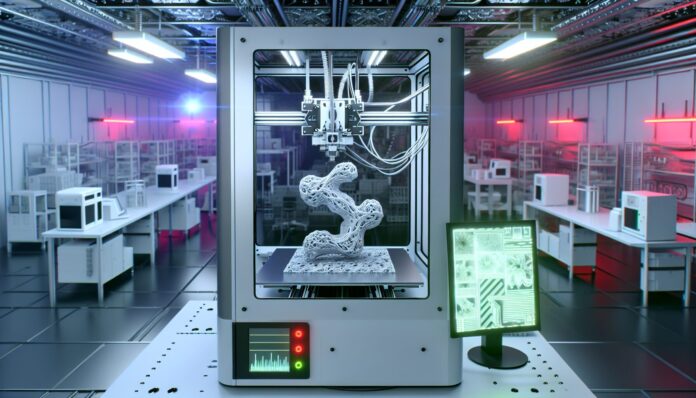

In a groundbreaking development, researchers have unveiled a new adaptive 3D printing technique that mimics the way natural organisms grow. This innovation could revolutionize how we manufacture complex structures, making them stronger, more efficient, and more sustainable.

Bioinspired 3D Printing: Learning from Nature

Nature has long been a source of inspiration for engineers and designers. From the intricate geometry of seashells to the lightweight strength of bird bones, biological structures often outperform man-made ones in terms of efficiency and resilience. Now, a team of scientists from the University of Freiburg and the University of California, Berkeley, have developed a 3D printing method that adapts in real-time, much like how living organisms grow in response to their environment.

Published in the journal Nature, the study introduces a technique called adaptive 3D printing, which allows the printer to modify its printing path and material deposition based on feedback during the printing process. This dynamic approach contrasts with traditional 3D printing, where the entire object is pre-designed and printed layer by layer without deviation.

How Adaptive 3D Printing Works

The core of this innovation lies in a feedback loop that integrates sensors and algorithms into the printing process. As the printer lays down material, it continuously monitors the structure’s geometry and mechanical properties. If it detects any deviation or stress, it adjusts the printing parameters in real-time—changing the direction, speed, or amount of material being deposited.

This method is inspired by how plants and animals grow. For example, tree branches grow thicker in areas experiencing more stress, and bones remodel themselves based on the loads they bear. By mimicking this adaptive behavior, the new 3D printing technique can create structures that are not only more efficient in material usage but also more robust under mechanical stress.

Applications in Engineering and Medicine

The potential applications of adaptive 3D printing are vast. In aerospace and automotive industries, it could lead to lighter and stronger components that adapt to stress during use. In architecture, it could enable the construction of buildings that respond to environmental conditions like wind or seismic activity.

In the medical field, adaptive printing could be used to create implants or prosthetics that better match the patient’s anatomy and adapt to their movements. For example, a bone scaffold printed with this method could adjust its internal structure to promote better healing and integration with the body.

Moreover, this technique could significantly reduce material waste. By only reinforcing areas that need it, manufacturers can use less material without compromising strength—an important step toward more sustainable production.

Challenges and Future Directions

While the results are promising, adaptive 3D printing is still in its early stages. One of the main challenges is the complexity of integrating real-time sensing and control into existing 3D printers. The system must be fast and accurate enough to make adjustments on the fly, which requires advanced hardware and software.

Another challenge is the development of materials that can respond predictably to changes in the printing process. The researchers used a photopolymer resin in their experiments, but future work may explore other materials, including metals and biocompatible polymers.

Looking ahead, the team envisions a future where 3D printers are not just tools for fabrication but intelligent systems capable of learning and adapting. This could open the door to a new era of manufacturing—one that is more aligned with the principles of nature and capable of producing structures that are both functional and beautiful.

As additive manufacturing continues to evolve, innovations like adaptive 3D printing highlight the importance of interdisciplinary research, combining biology, engineering, and computer science to push the boundaries of what’s possible.

Source: Nature