Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a groundbreaking 3D printing nozzle capable of printing with two different materials simultaneously. This innovation could significantly enhance the speed, precision, and versatility of additive manufacturing processes across industries.

Dual-Material 3D Printing: A Game-Changer

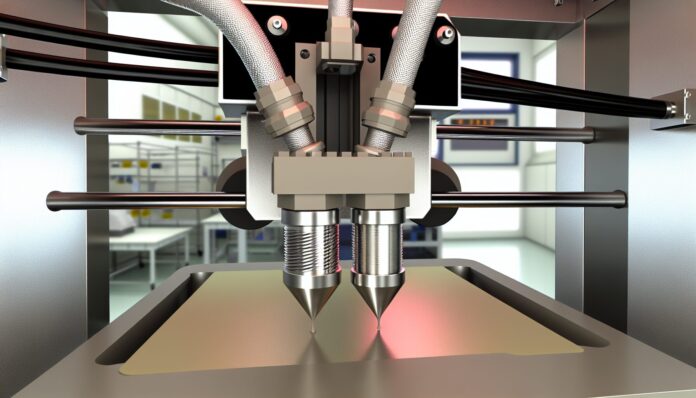

The new nozzle, developed by ORNL’s Manufacturing Demonstration Facility, introduces a novel approach to material deposition. Unlike traditional single-material extrusion systems, this nozzle can switch between two materials on the fly or blend them during the printing process. This capability allows for the creation of parts with varying mechanical properties, densities, or thermal characteristics within a single print job.

According to the researchers, the nozzle uses a multiplexing technique that enables rapid switching between materials without the need for multiple print heads or time-consuming tool changes. This not only reduces print time but also minimizes material waste and improves overall efficiency.

How the Multiplexing Nozzle Works

The nozzle design incorporates two separate material feed lines that converge at a single extrusion point. A high-speed valve system controls the flow of each material, allowing for precise control over the composition of the printed object. The system can either alternate materials layer by layer or mix them in varying ratios to create gradient structures.

This level of control opens up new possibilities for multi-functional parts. For example, a single component could have a rigid core for strength and a flexible outer layer for impact resistance. In aerospace or automotive applications, this could lead to lighter, more efficient parts with tailored performance characteristics.

Applications and Industry Impact

The ability to print with multiple materials in a single pass has far-reaching implications. In the aerospace sector, it could enable the production of lightweight components with integrated thermal or electrical properties. In healthcare, it could facilitate the creation of prosthetics or implants that combine hard and soft materials for better patient comfort and functionality.

Additionally, the technology could streamline the production of complex assemblies by reducing the need for post-processing or assembly of multiple parts. This aligns with the broader goals of additive manufacturing: reducing waste, shortening production cycles, and enabling on-demand manufacturing.

Future Development and Commercialization

While the technology is still in the research phase, ORNL is actively collaborating with industry partners to explore commercialization opportunities. The team is also working on scaling the nozzle for use in larger industrial 3D printers and expanding its compatibility with a wider range of materials, including metals, polymers, and composites.

This development is part of a broader push by the U.S. Department of Energy to advance manufacturing technologies that support energy efficiency, national security, and economic competitiveness. As additive manufacturing continues to evolve, innovations like this dual-material nozzle will play a critical role in shaping the future of production.

Source: Tom’s Hardware