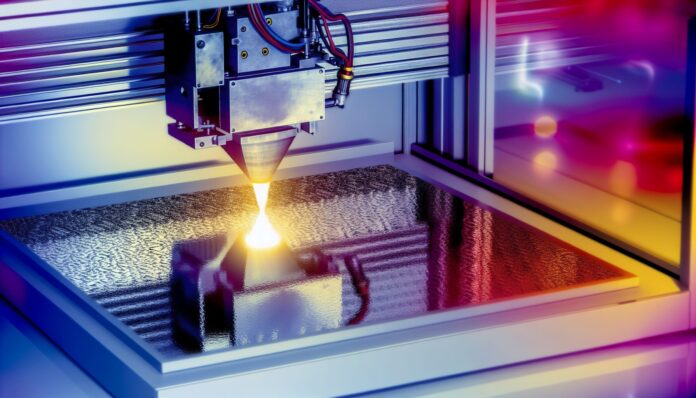

Researchers at the National Institute of Standards and Technology (NIST) have made a breakthrough in understanding how laser light behaves during metal 3D printing. Their findings could significantly improve the quality and reliability of parts produced through laser powder bed fusion (LPBF), one of the most widely used metal additive manufacturing techniques.

Understanding Laser-Material Interaction in Metal 3D Printing

Laser powder bed fusion (LPBF) is a metal 3D printing process where a high-powered laser selectively melts metal powder layer by layer to build a part. While the process is widely adopted in aerospace, medical, and automotive industries, it still faces challenges in achieving consistent part quality. One of the lesser-understood aspects of LPBF is how the laser light interacts with the powder and the surrounding environment during printing.

NIST researchers have now shown that light doesn’t just travel directly from the laser to the powder bed. Instead, it reflects off the walls of the melt pool — the tiny pool of molten metal created by the laser — and these reflections can significantly affect the energy distribution and melting behavior.

“We found that the laser light reflects off the walls of the melt pool and can even bounce back into the laser beam itself,” said NIST physicist Samuel Clark. “This means the energy input is more complex than previously thought.”

Why Reflected Light Matters in Additive Manufacturing

These reflections can lead to localized overheating or underheating, which in turn affects the microstructure and mechanical properties of the final part. Inconsistent melting can cause defects such as porosity, cracking, or residual stress — all of which compromise the integrity of the printed component.

By using high-speed cameras and advanced sensors, the NIST team was able to capture how light reflects within the melt pool in real time. Their experiments revealed that the geometry of the melt pool and the angle of the laser beam play a critical role in how light is distributed. This insight could help engineers better control the process by adjusting laser parameters or modifying scan strategies to minimize unwanted reflections.

“Understanding these reflections gives us a new lever to pull in optimizing the process,” said Clark. “It’s like discovering a hidden variable that we can now account for.”

Implications for Metal 3D Printing Quality and Standards

The findings have far-reaching implications for improving the repeatability and reliability of metal 3D printing. By incorporating the effects of reflected light into simulation models and process controls, manufacturers can better predict how a part will form and reduce the likelihood of defects.

This research also supports the development of industry standards for additive manufacturing. NIST plays a key role in creating measurement science and standards that help ensure quality across the industry. With this new understanding of laser behavior, standards bodies can refine guidelines for machine calibration, process monitoring, and part validation.

“This is a step toward more predictive and controlled manufacturing,” said Clark. “It helps us move from trial-and-error to science-based process design.”

Future Directions and Applications

Looking ahead, the NIST team plans to expand their research to different materials and laser configurations. They also aim to collaborate with industry partners to integrate these findings into commercial 3D printing systems. The ultimate goal is to enable manufacturers to produce high-performance metal parts with greater confidence and efficiency.

Applications for this research span across critical sectors. In aerospace, for example, where part failure is not an option, improved control over the printing process could lead to safer, lighter components. In the medical field, it could enable more precise implants and prosthetics. Even in energy and defense, where custom metal parts are often required, this advancement could streamline production and reduce costs.

As metal additive manufacturing continues to evolve, insights like these will be essential for unlocking its full potential. By shedding light—literally—on the hidden dynamics of laser-material interaction, NIST is helping to shape the future of industrial 3D printing.

Source: NIST.gov