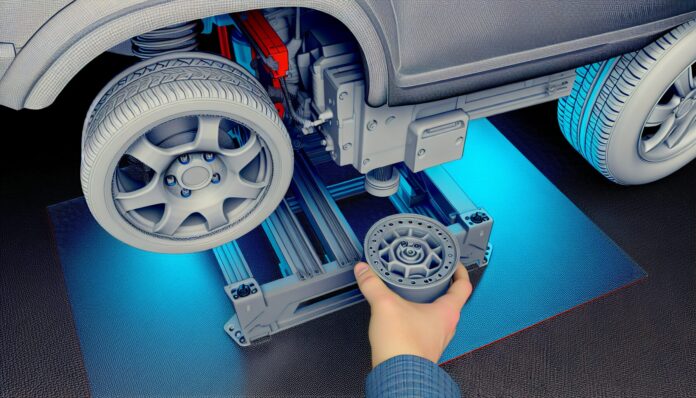

3D printing has come a long way from being a niche hobby to a powerful tool for DIYers and professionals alike. In a recent hands-on experience, a $300 3D printer proved it could do more than just print toys—it can fabricate functional car parts. Here’s how this budget-friendly machine is changing the game for automotive enthusiasts.

Affordable 3D Printing for Automotive Applications

The printer in question is the Anycubic Kobra 2, a sub-$300 FDM (Fused Deposition Modeling) 3D printer that offers impressive speed and quality for its price. With a maximum print speed of 250 mm/s and a direct drive extruder, it’s well-suited for printing strong, detailed parts using materials like PLA, PETG, and even TPU. The printer also features automatic bed leveling, a PEI-coated flexible build plate, and a 4.3-inch touchscreen interface, making it user-friendly for beginners and efficient for experienced users.

In the hands of a car enthusiast, this printer quickly proved its value. The first project? A custom bracket for a car’s interior trim. Designed in CAD software and printed in PETG for durability, the part fit perfectly and cost just a few cents in material. This kind of rapid prototyping and production is a game-changer for anyone working on custom or restoration projects.

From Prototyping to Production: Real-World Use Cases

3D printing car parts isn’t just about aesthetics—it’s about functionality. The article’s author used the printer to create a variety of components, including a replacement for a broken clip, a custom phone mount, and even a tool for aligning suspension components. These parts were not only functional but also saved time and money compared to ordering OEM replacements or fabricating parts by hand.

One of the key advantages of 3D printing in automotive applications is the ability to iterate quickly. If a part doesn’t fit perfectly, it can be redesigned and reprinted in a matter of hours. This flexibility is especially valuable for older vehicles where replacement parts may be hard to find or prohibitively expensive.

Materials Matter: Choosing the Right Filament

While PLA is the most common filament for beginners, it’s not always suitable for automotive use due to its low heat resistance. PETG and ABS are better choices for parts exposed to higher temperatures or mechanical stress. TPU, a flexible filament, is ideal for gaskets, bushings, or vibration-dampening components.

The Anycubic Kobra 2 handles these materials well, especially PETG, which offers a good balance of strength, flexibility, and ease of printing. The printer’s direct drive extruder and heated bed help reduce warping and improve layer adhesion, which are critical for producing durable parts.

The Future of DIY Car Repair with 3D Printing

As 3D printing technology becomes more accessible and affordable, its applications in the automotive world will only grow. From custom interior mods to functional engine bay components, the possibilities are nearly endless. Online communities and repositories like Thingiverse and Printables offer thousands of free designs, and CAD software like Fusion 360 or Tinkercad makes it easier than ever to create your own parts.

For under $300, the Anycubic Kobra 2 offers a compelling entry point into this world. It’s fast, reliable, and capable of producing parts that can stand up to real-world use. Whether you’re restoring a classic car, customizing your daily driver, or just looking to save money on repairs, a 3D printer like this could be one of the best tools in your garage.

Source: The Drive