Prusa Research, a major player in the desktop 3D printing world, is making waves again by reentering the tool changer arena. After years of development and a brief hiatus, the company has unveiled a new tool changer system that could reshape the landscape of multi-material FDM printing.

Prusa’s Return to Tool Changer Technology

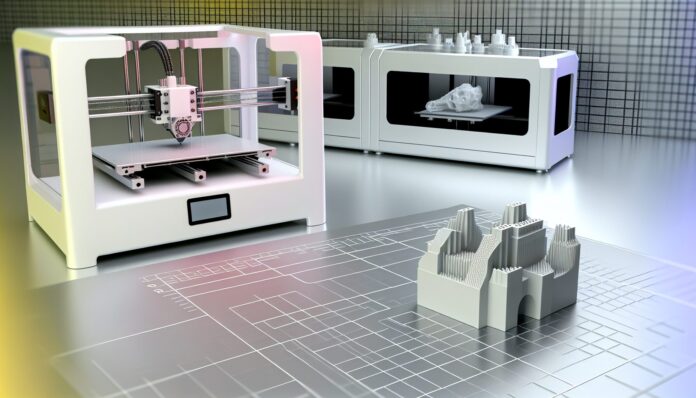

Tool changers in 3D printing allow a single printer to switch between multiple extruders or tools during a print job. This enables multi-material or multi-color printing, as well as the use of different nozzle sizes or specialized tools like laser engravers or pick-and-place heads. While companies like E3D and Bambu Lab have made significant strides in this area, Prusa had been relatively quiet—until now.

Josef Průša, founder of Prusa Research, recently confirmed that the company is actively developing a new tool changer system. This announcement comes after a long period of silence following the initial reveal of a prototype tool changer in 2019. That early version never made it to market, but the renewed effort suggests Prusa is ready to compete in this increasingly important segment of the 3D printing market.

Why Tool Changers Matter in 3D Printing

Tool changers are a game-changer for FDM 3D printing. Traditional multi-material printing often relies on dual-extrusion systems, which can be bulky, prone to clogging, and limited in flexibility. Tool changers, on the other hand, allow for cleaner transitions between materials and more efficient use of print time and space.

Companies like E3D with their ToolChanger platform and Bambu Lab with their AMS (Automatic Material System) have demonstrated the potential of this technology. Prusa’s reentry into this space could bring more competition, innovation, and ultimately better options for consumers and professionals alike.

Prusa’s approach is expected to be open-source, in line with the company’s philosophy. This could encourage community-driven development and third-party tool head designs, much like the ecosystem that has grown around the E3D ToolChanger.

Technical Challenges and Innovations

Developing a reliable tool changer system is no small feat. It requires precise mechanical alignment, robust software integration, and a user-friendly interface. Prusa’s previous experience with the Multi-Material Upgrade (MMU) for the MK3 series gave them a foundation in multi-material printing, but a true tool changer is a more complex endeavor.

According to Průša, the new system will be modular and scalable, allowing users to start with a basic setup and expand as needed. This flexibility could make it appealing to both hobbyists and professionals. The company is also focusing on minimizing tool change time and ensuring high repeatability, which are critical for maintaining print quality across multiple tools.

While no official release date has been announced, Prusa has hinted that the system is in advanced stages of development. Beta testing is expected to begin soon, with a full release likely in the next year.

Implications for the 3D Printing Industry

Prusa’s reentry into the tool changer market could have significant implications. As one of the most trusted names in desktop 3D printing, their endorsement of this technology could accelerate its adoption. It also puts pressure on competitors to innovate and improve their own systems.

For users, this means more choices and potentially lower prices as competition heats up. It also opens the door to more complex and creative applications, from multi-material prototypes to functional parts with embedded components.

In the broader context, the move reflects a shift in the 3D printing industry toward more versatile and capable machines. As users demand more from their printers, manufacturers are responding with systems that can do more than just extrude plastic. Tool changers are a key part of that evolution.

Whether Prusa’s new system will live up to the hype remains to be seen, but one thing is clear: the tool changer wars are heating up, and Prusa is back in the fight.

Source: Tom’s Hardware