As the demand for energy-efficient and scalable data centers continues to surge, thermal management technologies are becoming more critical than ever. Alloy Enterprises, a Massachusetts-based additive manufacturing startup, is stepping up to the challenge by using its proprietary aluminum 3D printing platform to develop next-generation cooling solutions tailored for data centers.

Aluminum 3D Printing for Efficient Thermal Management

Alloy Enterprises was founded in 2020 with a mission to unlock the potential of aluminum in additive manufacturing. Unlike powder-based methods, Alloy’s approach uses laminated aluminum sheets that are cut and bonded layer by layer. This sheet-based additive manufacturing method allows for the production of fully solid, scalable aluminum parts with complex geometries, high thermal conductivity, and structural integrity.

According to co-founder and CEO Ali Forsyth, this unique process enables Alloy to produce parts faster and at a lower cost than traditional metal 3D printing methods. The company is focusing on applications where aluminum’s lightweight and thermal properties are advantageous, with data center cooling systems emerging as a key market.

3D Printed Heat Exchangers for Data Centers

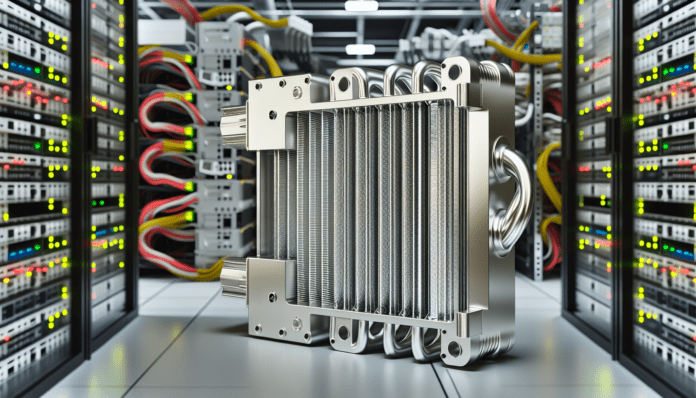

Data centers generate immense heat and require highly efficient cooling systems to maintain performance and prevent downtime. Traditional heat exchangers often face limitations in design complexity and thermal performance due to manufacturing constraints. Alloy Enterprises is addressing these challenges by 3D printing custom aluminum heat exchangers with optimized internal geometries that enhance heat transfer and fluid flow.

Forsyth explains that Alloy’s printed heat exchangers can be tailored to specific customer requirements, including compact form factors, improved thermal efficiency, and reduced manufacturing lead times. The company is currently working with several partners in the data center industry to develop and test these advanced cooling components.

Advantages of Alloy’s Sheet-Based Additive Manufacturing

Alloy’s patented process offers several distinct benefits over conventional powder bed fusion techniques:

- Material Efficiency: The sheet-based method reduces waste and eliminates the need for powder handling or recycling.

- Cost-Effective Scaling: Parts can be produced in batches, making the process more suitable for medium- to high-volume production.

- Mechanical Strength: The resulting parts are fully dense and exhibit mechanical properties comparable to wrought aluminum.

- Design Freedom: Internal channels and complex geometries can be created without the need for support structures.

These capabilities enable Alloy Enterprises to meet the performance and scalability demands of industries like aerospace, automotive, and now, data infrastructure.

The Road Ahead for Alloy Enterprises

With its recent funding and growing partnerships, Alloy Enterprises is poised to scale up its manufacturing capabilities and expand its footprint in the data center market. The company plans to increase production capacity at its Burlington, Massachusetts facility and continue developing new applications for its aluminum 3D printing technology.

As data centers grow in complexity and energy consumption, the need for efficient, compact, and customizable cooling systems will only intensify. Alloy Enterprises aims to be at the forefront of this shift, using additive manufacturing to deliver thermal solutions that are both innovative and practical.

Source: 3D Printing Industry