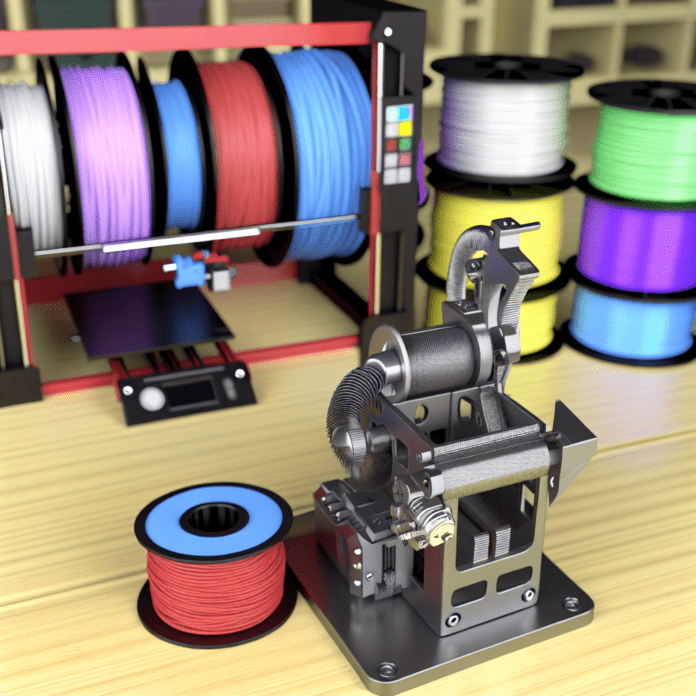

Switching filaments during a 3D print job—especially in multi-material setups—can be a time-consuming hassle. A recent DIY innovation aims to change that by introducing a compact, efficient speed loader for filament spools, designed to streamline this essential part of the 3D printing process.

Streamlining Filament Changes for Multi-Material 3D Printing

Multi-material 3D printing has become increasingly popular, allowing users to combine different colors, materials, or support structures in a single print. However, this process often requires frequent filament swaps, which can lead to downtime and misfeeds if not handled carefully. To address this challenge, [David] has developed a speed loader mechanism that enables rapid and reliable filament changes between print jobs or even mid-print.

The design consists of a spring-loaded clip that holds a short length of filament. When engaged, this clip can quickly insert the filament into the Bowden tube or direct drive extruder without the typical fuss of manual feeding. The mechanism ensures the filament is properly aligned and seated, reducing the risk of jams or under-extrusion.

How the 3D Printer Filament Speed Loader Works

The core of the design is a spring-tensioned latch that holds a pre-cut length of filament. The user loads this piece into the loader, and once the printer is ready, they simply press a button or lever to release the filament into the extruder. This action mimics the reloading of a magazine clip in firearms—hence the term “speed loader.” The result is a filament swap process that takes only seconds, compared to the typical minute or more.

To make the system even more efficient, [David] designed the loader to be modular. Multiple units can be pre-loaded with different filaments and swapped out as needed. This makes it ideal for print farms, educational settings, or any workflow where time and reliability are critical.

DIY 3D Printing Innovation: Building the Speed Loader

True to the open-source spirit of the 3D printing community, the speed loader is fully DIY and can be printed using common FDM printers. The parts are designed for easy assembly, with minimal hardware required—typically just a few springs, screws, and printed components. [David] has made the design files publicly available, allowing others to download, print, and adapt the loader to their specific printer setup.

The loader works best with Bowden-style printers but could also be adapted for direct-drive systems with minor modifications. The design emphasizes simplicity and reliability, ensuring that even novice makers can build and use it with confidence.

Applications and Future Potential

While the current version of the speed loader is designed for manual operation, there’s potential for automation. For example, a motorized version could be integrated into a tool-changing head or automated filament switching system. Such developments could bring this DIY concept closer to the capabilities of high-end multi-material systems like Prusa’s MMU or Bambu Lab’s AMS, but at a fraction of the cost.

This kind of grassroots innovation highlights the power of the 3D printing community to solve real-world problems with accessible, affordable solutions. Whether you’re running a print farm or simply want to reduce downtime between filament changes, this speed loader is a clever tool worth exploring.

Source: Hackaday