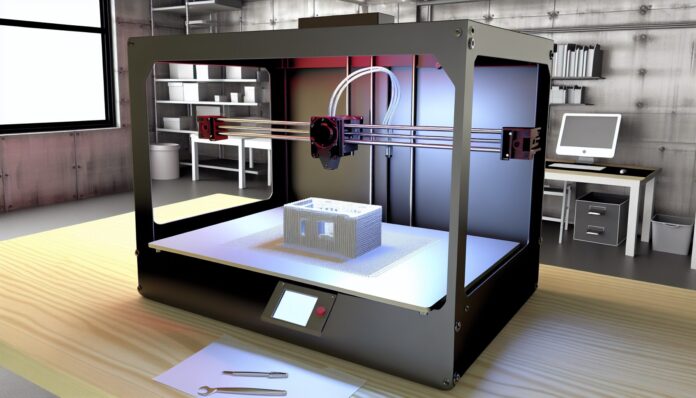

3D printing has transformed how we prototype, manufacture, and innovate. But despite its promise, the technology comes with limitations that are often overlooked. Whether you’re a hobbyist or a professional, understanding these challenges is essential to making the most of additive manufacturing.

3D Printing Isn’t as Plug-and-Play as It Seems

One of the biggest misconceptions about 3D printing is that it’s as simple as pressing a button. In reality, successful 3D printing requires a deep understanding of slicing software, printer calibration, material properties, and post-processing. Even with pre-configured profiles, users often need to tweak settings like temperature, speed, and retraction to get optimal results. Beginners may find the learning curve steep, especially when dealing with failed prints or hardware issues.

Print Quality Can Be Inconsistent

While 3D printers have improved significantly in recent years, print quality can still vary widely. Factors such as filament quality, ambient temperature, and even humidity can affect the final output. Layer lines, warping, and stringing are common issues that require experience and patience to resolve. High-resolution prints are possible, but they often require slower speeds and longer print times, which can be a trade-off for users seeking efficiency.

Material Limitations Still Exist

Although the range of printable materials has expanded, most consumer-grade 3D printers are limited to thermoplastics like PLA, ABS, and PETG. Advanced materials such as carbon fiber composites, metal, or high-temperature polymers require specialized equipment and safety precautions. Additionally, not all materials are food-safe, UV-resistant, or suitable for mechanical stress, which limits their use in functional or outdoor applications.

3D Printing Is Not Always Cost-Effective

While 3D printing can save money on prototyping and small-batch production, it’s not always the cheapest option. The cost of filament, maintenance, failed prints, and electricity can add up quickly. Moreover, time is a hidden cost—complex prints can take hours or even days to complete. For mass production, traditional manufacturing methods like injection molding are still more economical and scalable.

Post-Processing Is Often Necessary

Many newcomers are surprised to learn that a finished print often requires additional work. Supports need to be removed, surfaces may need sanding, and parts might require painting or sealing. In industrial settings, post-processing can include annealing, vapor smoothing, or even CNC machining. These steps add time and complexity to the workflow, making 3D printing less convenient than it initially appears.

The Future of 3D Printing: Promise and Pragmatism

Despite these challenges, 3D printing continues to evolve. Innovations in materials, software, and printer design are making the technology more accessible and reliable. However, it’s important to approach 3D printing with realistic expectations. Understanding its limitations allows users to better plan projects, reduce frustration, and ultimately achieve better results.

Whether you’re printing a cosplay prop or prototyping a new product, knowing these uncomfortable truths can help you make informed decisions and get the most out of your 3D printing experience.

Source: How-To Geek