As 3D printing continues to evolve, industry experts are looking ahead to 2026 with bold predictions about where additive manufacturing is headed. From industrial-scale production to breakthroughs in polymer materials, the next few years promise significant transformation across sectors.

Industrial 3D Printing: Scaling Up Production

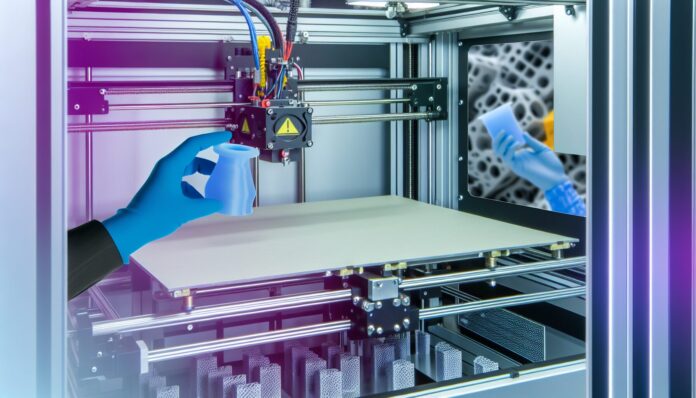

One of the most anticipated developments in 3D printing by 2026 is the widespread adoption of additive manufacturing for industrial-scale production. Companies are moving beyond prototyping and small-batch manufacturing to full-scale production runs using 3D printing technologies. This shift is driven by improvements in speed, reliability, and cost-efficiency of industrial 3D printers.

Manufacturers in aerospace, automotive, and healthcare are already integrating additive manufacturing into their production lines. By 2026, experts predict that 3D printing will become a standard tool for producing end-use parts, especially in applications where customization, lightweighting, and complex geometries are critical. The ability to produce parts on-demand and closer to the point of use also supports more resilient and localized supply chains.

Polymer Additive Manufacturing: Material Innovation

Polymer-based 3D printing is expected to see significant advancements by 2026, particularly in material science. New high-performance polymers are being developed to meet the demands of industrial applications, offering improved strength, heat resistance, and chemical stability. These materials will enable 3D printing to compete more directly with traditional manufacturing methods in terms of part performance.

In addition, sustainability is becoming a key focus. Biodegradable and recyclable polymers are gaining traction, aligning with global efforts to reduce environmental impact. Companies are also exploring closed-loop systems where waste material is reused in the printing process, further enhancing the eco-friendliness of additive manufacturing.

Software and Automation: Enhancing Workflow Efficiency

Another area poised for growth is the software ecosystem surrounding 3D printing. By 2026, we can expect more advanced design tools, simulation software, and automated workflows that streamline the entire additive manufacturing process. AI-driven optimization will play a larger role in part design, print preparation, and quality assurance.

Automation will also extend to post-processing, with integrated systems that clean, cure, and finish parts with minimal human intervention. These improvements will reduce labor costs and increase throughput, making 3D printing more viable for high-volume production.

Market Outlook and Industry Impact

The global 3D printing market is projected to grow significantly by 2026, with estimates ranging from $30 billion to $50 billion depending on the source. This growth will be fueled by increased adoption across industries, continued innovation in hardware and materials, and the maturation of additive manufacturing as a production technology.

As the technology becomes more accessible and cost-effective, small and medium-sized enterprises (SMEs) will also benefit, using 3D printing to create custom products, reduce inventory, and accelerate product development cycles. Education and workforce training will be essential to support this growth, ensuring that engineers and technicians are equipped with the skills needed to operate and maintain advanced 3D printing systems.

In summary, the future of 3D printing looks bright. By 2026, we can expect to see additive manufacturing firmly established as a mainstream production method, with polymer materials leading the charge in innovation and sustainability.

Source: 3DPrint.com