The world of additive manufacturing continues to evolve at an impressive pace. In this week’s roundup, we explore new developments in U.S.-based 3D printing production, innovative optical force sensors advancing robotics, and other significant updates that signal the growing impact of 3D printing across industries.

U.S. Expansion of 3D Printing Manufacturing

One of the main highlights this week is the continued expansion of 3D printing production within the United States. Several companies are investing in domestic manufacturing capabilities to reduce reliance on overseas supply chains and to bolster national industrial resilience. This shift aligns with broader initiatives to localize advanced manufacturing and improve supply chain responsiveness, particularly in sectors such as aerospace, automotive, and healthcare.

For instance, additive manufacturing firms are opening new facilities and partnering with U.S.-based suppliers to scale production. These efforts are also being supported by government grants and public-private partnerships aimed at fostering innovation and creating high-tech jobs. The move is expected to strengthen the U.S. position in global manufacturing while enabling faster product development cycles through on-demand production.

Breakthrough in Optical Force Sensors for Robotics

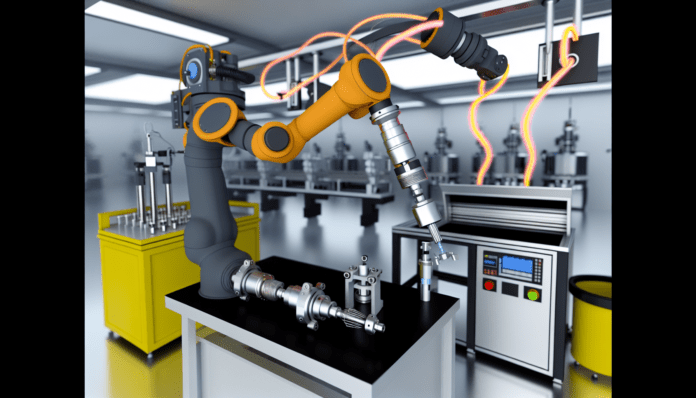

Another noteworthy innovation comes from the field of robotics, where researchers have developed new optical force sensors using 3D printing techniques. These sensors are designed to mimic the sensitivity of human touch, enabling robots to perform delicate tasks with increased precision. The technology leverages flexible materials and embedded optics to measure pressure and tactile feedback.

Such sensors are crucial for applications in medical robotics, prosthetics, and collaborative robots (cobots) that work alongside humans. The ability to 3D print these components offers not only cost advantages but also customization options tailored to specific robotic platforms. As this technology matures, it could significantly enhance the dexterity and safety of robotic systems in various industries.

Other Key Developments in Additive Manufacturing

Beyond production and sensor innovation, the additive manufacturing sector has seen a range of other advancements this week. These include:

- New material formulations optimized for high-temperature applications, particularly in aerospace and energy sectors.

- Software updates that enhance print simulation accuracy and reduce design-to-manufacture time.

- Collaborative research projects between universities and industry partners to explore biofabrication and sustainable printing practices.

These developments reflect a broader trend of integrating 3D printing into mainstream manufacturing processes. As hardware, software, and materials continue to improve, the technology is becoming a cornerstone of Industry 4.0 strategies worldwide.

Applications and Industry Impact

The innovations highlighted this week demonstrate the versatility and growing maturity of 3D printing. From enabling localized production in the U.S. to equipping robots with tactile sensing capabilities, additive manufacturing is driving efficiency, customization, and innovation across sectors. Key industries benefiting from these advancements include:

- Healthcare: Custom implants, surgical tools, and prosthetics made using biocompatible materials.

- Aerospace: Lightweight, complex components that reduce fuel consumption and improve performance.

- Automotive: Rapid prototyping and production of spare parts and tooling.

- Consumer Goods: Personalized products and limited-run designs that cater to niche markets.

As adoption grows, so too does the need for skilled professionals and robust standards to guide quality and safety in 3D printed products. Training programs, regulatory frameworks, and cross-sector collaboration will play a vital role in shaping the future of this transformative technology.

Stay tuned for more weekly updates as we continue to track the latest in 3D printing innovation.

Source: 3DPrint.com