In a groundbreaking demonstration of large-scale additive manufacturing, the University of Maine has unveiled a 3D-printed boat that could signal a new era in maritime construction. This innovation not only showcases the capabilities of modern 3D printing but also hints at a future where ships and other large structures are built faster, cheaper, and more sustainably.

Large-Scale 3D Printing in Shipbuilding

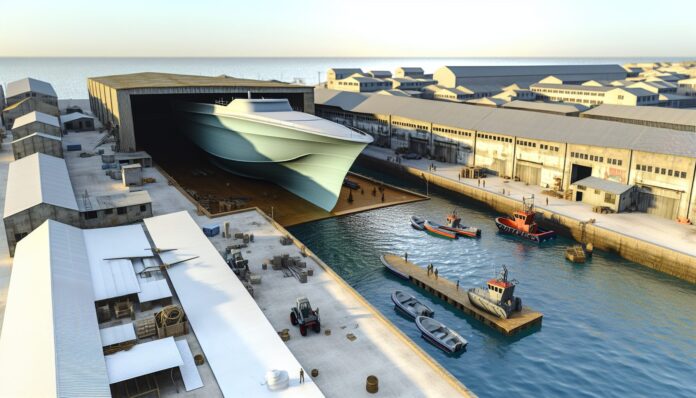

The University of Maine’s Advanced Structures and Composites Center (ASCC) has developed a 3D-printed boat using one of the world’s largest polymer 3D printers. The boat, named 3Dirigo, measures 25 feet long and weighs 5,000 pounds. It was printed in just 72 hours using a carbon-fiber-reinforced plastic material. This project not only set a Guinness World Record for the largest 3D-printed boat but also demonstrated the feasibility of using additive manufacturing for full-scale marine vessels.

The printer used in this project is capable of producing objects up to 100 feet long, 22 feet wide, and 10 feet high. It uses a thermoplastic material reinforced with 50% wood cellulose fiber, making it both strong and sustainable. The material is recyclable and derived from renewable resources, aligning with growing environmental concerns in manufacturing.

Benefits of 3D Printing for Marine Applications

Traditional shipbuilding is a time-consuming and labor-intensive process that involves welding, cutting, and assembling numerous components. 3D printing, by contrast, allows for the creation of complex geometries in a single build, reducing the need for multiple parts and manual labor. This can significantly cut down production time and costs.

Moreover, additive manufacturing enables rapid prototyping and customization. Designers can quickly iterate on hull shapes, internal structures, and other features to optimize performance and efficiency. This flexibility is particularly valuable for military, research, and commercial vessels that require specialized configurations.

Challenges and Future Potential

While the 3D-printed boat is a promising proof of concept, there are still challenges to overcome before this technology can be widely adopted in the maritime industry. Material durability, especially in harsh marine environments, remains a key concern. Long-term testing is needed to ensure that 3D-printed components can withstand saltwater corrosion, UV exposure, and mechanical stress.

Another hurdle is scaling up production. Although the University of Maine’s printer is among the largest in the world, producing full-sized ships or submarines would require even more advanced equipment and infrastructure. However, the potential benefits—reduced costs, faster production, and environmental sustainability—make this a worthwhile pursuit.

Looking ahead, the integration of 3D printing with other advanced technologies such as digital twin modeling, AI-driven design, and automated quality control could further enhance the capabilities of additive manufacturing in shipbuilding. The U.S. Department of Defense and private industry partners are already exploring these possibilities, indicating strong interest and investment in this emerging field.

Broader Implications for Additive Manufacturing

The success of the 3Dirigo project has implications beyond the maritime sector. It demonstrates that large-scale 3D printing can be used to manufacture complex, high-performance structures in a fraction of the time required by traditional methods. This could revolutionize industries such as aerospace, construction, and energy, where large, custom components are often needed.

For example, wind turbine blades, bridge components, and even housing units could be produced using similar techniques. The use of bio-based, recyclable materials also supports the shift toward greener manufacturing practices, aligning with global sustainability goals.

As additive manufacturing continues to evolve, projects like the 3D-printed boat from the University of Maine serve as powerful examples of what’s possible when innovation meets real-world application.

Source: BBC