The U.S. Navy is taking a major step forward in modernizing its logistics and maintenance operations by integrating 3D printing technology directly into its fleet. This move is set to revolutionize how naval vessels handle repairs and part replacements while at sea, offering a faster, more flexible alternative to traditional supply chains.

3D Printing at Sea: A Strategic Shift

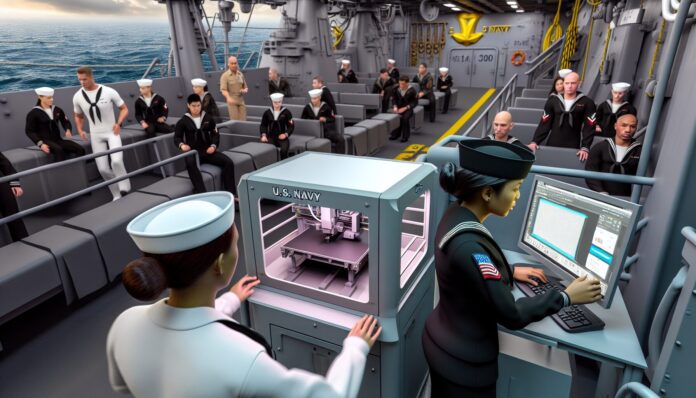

In a significant development, the Navy has begun deploying additive manufacturing (AM) systems aboard its ships, enabling crews to fabricate critical components on demand. This initiative is part of a broader effort to enhance operational readiness and reduce downtime caused by part shortages or logistical delays.

Rear Adm. Jason Lloyd, chief engineer and deputy commander for Naval Sea Systems Command (NAVSEA), emphasized the importance of this capability: “We are no longer just experimenting with 3D printing—we are operationalizing it.” The Navy’s goal is to empower sailors with the tools and training needed to produce mission-critical parts wherever and whenever they are needed.

From Prototypes to Production: Navy’s Additive Manufacturing Journey

The Navy’s journey with 3D printing began over a decade ago with small-scale prototyping and research. Over time, the technology matured, and the service began to explore more practical applications. Today, the Navy operates several Additive Manufacturing Centers of Excellence (AM CoEs), including facilities at Norfolk Naval Shipyard and Puget Sound Naval Shipyard, which support both training and production.

These centers have been instrumental in developing the Navy’s AM workforce and validating parts for use in real-world operations. The Navy has already certified over 500 3D-printed parts for shipboard use, ranging from valve covers to specialized tools and brackets. Some of these components are even being used in nuclear-powered vessels, demonstrating the high level of trust in the technology’s reliability and safety.

Benefits of Onboard 3D Printing for Naval Operations

Deploying 3D printers directly to ships offers several strategic advantages. First and foremost, it reduces the Navy’s dependence on long and often vulnerable supply chains. In remote or contested environments, waiting for a replacement part to arrive can take days or even weeks. With onboard AM capabilities, sailors can produce the needed part in hours.

Additionally, 3D printing allows for the customization of parts to meet specific mission requirements. This flexibility is particularly valuable in dynamic operational environments where standard components may not always be ideal. The technology also supports sustainability by reducing waste and enabling the recycling of materials.

Another key benefit is cost savings. While the initial investment in AM equipment and training is significant, the long-term savings from reduced inventory, shipping, and downtime are substantial. The Navy estimates that additive manufacturing could save millions of dollars annually across its fleet.

Training and Certification: Building a Skilled AM Workforce

To ensure the success of its AM initiative, the Navy is investing heavily in training and certification programs. Sailors are being taught how to operate and maintain 3D printers, design parts using CAD software, and follow strict quality assurance protocols. The Navy has also established a rigorous certification process to ensure that all printed parts meet the necessary performance and safety standards.

One example is the Joint Additive Manufacturing Model Exchange (JAMMEX), a digital repository that allows sailors to access approved 3D models for printing. This system ensures consistency and quality across the fleet while enabling rapid deployment of new designs as they are validated.

Looking Ahead: The Future of 3D Printing in the Navy

The Navy’s commitment to additive manufacturing is only expected to grow in the coming years. Future plans include expanding the number of ships equipped with 3D printers, increasing the range of printable materials, and integrating AM into more aspects of ship maintenance and logistics.

There is also interest in exploring advanced technologies such as metal additive manufacturing and hybrid systems that combine 3D printing with traditional machining. These innovations could further enhance the Navy’s ability to produce complex, high-performance parts on demand.

As the Navy continues to refine its AM capabilities, it is also collaborating with other branches of the military, industry partners, and academic institutions to share knowledge and accelerate innovation. This collaborative approach ensures that the Navy remains at the forefront of additive manufacturing technology and is well-prepared to meet the challenges of modern naval warfare.

Source: WorkBoat