Metal 3D printing has long been associated with industrial-scale operations, requiring specialized environments and safety protocols. But a new player is changing the game. The Gauss MT90, a metal 3D printer developed by and MetalPrinting, is designed to bring metal additive manufacturing into office settings—safely and efficiently—by eliminating the need for hazardous metal powders.

Paste-Based Metal Extrusion: A Safer Alternative

Traditional metal 3D printing methods, such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM), rely on fine metal powders and high-powered lasers or electron beams. These processes require strict safety measures due to the flammability and toxicity of metal powders, as well as the high temperatures involved. The Gauss MT90 takes a different approach by using Paste-based Metal Extrusion (PME), a technology that combines metal particles with a binder to form a paste.

This paste is extruded similarly to how Fused Deposition Modeling (FDM) printers work with thermoplastics. Once the part is printed, it undergoes a debinding and sintering process to remove the binder and fuse the metal particles into a solid object. This method significantly reduces the risks associated with powder handling and makes the process more accessible to non-industrial users.

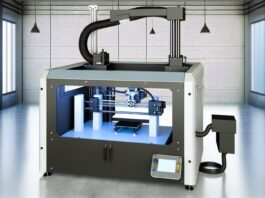

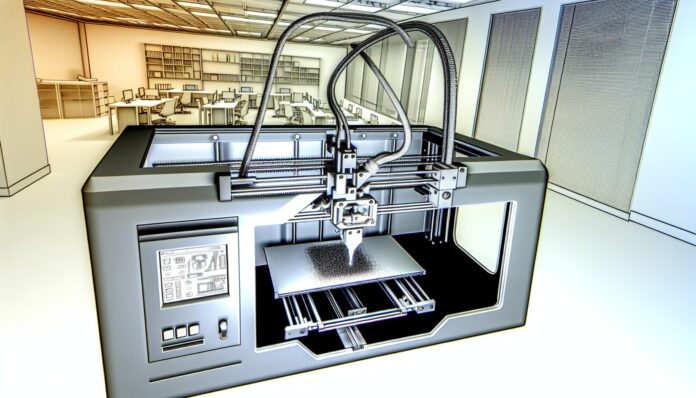

Gauss MT90: Designed for the Office

The Gauss MT90 is engineered with office environments in mind. It features a fully enclosed build chamber, integrated air filtration, and a compact footprint. The printer supports a variety of metal pastes, including stainless steel and copper, and is compatible with standard electrical outlets, eliminating the need for industrial power sources.

One of the standout features of the MT90 is its user-friendly interface and automated material handling system. The printer is designed to be plug-and-play, with minimal setup required. This makes it ideal for engineers, designers, and researchers who need to prototype or produce small batches of metal parts without outsourcing to a third-party service.

Applications and Advantages of PME Technology

Paste-based metal extrusion opens up a range of applications across industries. In aerospace and automotive sectors, it can be used for rapid prototyping of metal components. In healthcare, it enables the production of custom surgical tools and implants. The technology is also well-suited for educational institutions and R&D labs, where safety and ease of use are paramount.

Compared to traditional metal 3D printing, PME offers several advantages:

- Safety: No need to handle or store reactive metal powders.

- Cost-effectiveness: Lower equipment and material costs.

- Accessibility: Can be used in standard office or lab environments.

- Simplicity: Easier setup and operation with minimal training.

However, it’s important to note that PME may not match the mechanical properties or resolution of parts produced by high-end powder bed fusion systems. Still, for many use cases, especially in prototyping and low-volume production, the trade-offs are acceptable.

The Future of Metal 3D Printing in the Office

The Gauss MT90 represents a significant step toward democratizing metal additive manufacturing. By removing the barriers of cost, complexity, and safety, it allows more organizations to explore the benefits of metal 3D printing. As PME technology continues to evolve, we can expect improvements in material options, part quality, and process automation.

With the rise of distributed manufacturing and the need for rapid, localized production, office-friendly metal 3D printers like the Gauss MT90 could play a crucial role in reshaping how products are designed and made.

Source: Tom’s Hardware