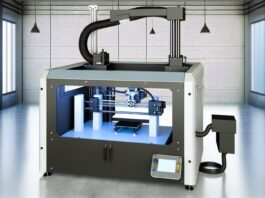

At CES 2026, AtomForm made waves in the additive manufacturing world by unveiling its latest innovation: the Palette 300. This industrial-grade 3D printer features a groundbreaking 12-nozzle system, enabling simultaneous multi-material printing with unprecedented speed and precision. Designed for professionals and advanced users, the Palette 300 is poised to redefine what’s possible in multi-material 3D printing.

Revolutionizing Multi-Material 3D Printing

The Palette 300 stands out with its unique 12-nozzle printhead, allowing users to print with up to 12 different materials or colors in a single job. Unlike traditional single- or dual-extruder systems, this setup eliminates the need for filament switching mid-print, significantly reducing downtime and improving print quality. Each nozzle is independently controlled, enabling seamless transitions between materials and minimizing cross-contamination.

AtomForm’s proprietary software coordinates the complex extrusion process, ensuring precise deposition of each material. This opens the door to creating parts with integrated functions—such as combining rigid and flexible materials, conductive and insulating elements, or even embedding support structures that dissolve post-print.

Industrial-Grade Performance and Build Quality

Built with a robust aluminum frame and high-precision linear rails, the Palette 300 is engineered for reliability and repeatability. It features a large build volume of 300 x 300 x 300 mm, making it suitable for prototyping, functional parts, and small-batch production. The printer supports a wide range of thermoplastics, including PLA, ABS, PETG, TPU, and engineering-grade materials like nylon and carbon-fiber composites.

To maintain optimal print conditions, the Palette 300 includes an actively heated build chamber and a filament drying system integrated into the machine. These features ensure consistent material performance, especially when working with moisture-sensitive filaments. The printer also includes automatic bed leveling, a touchscreen interface, and remote monitoring capabilities via Wi-Fi and Ethernet.

Applications Across Industries

The Palette 300 is designed to meet the needs of professionals in industries such as aerospace, automotive, healthcare, and consumer electronics. Its ability to print complex, multi-material parts in a single run reduces assembly time and enables the creation of more sophisticated components. For example, engineers can prototype overmolded parts, embedded gaskets, or multi-color branding elements without post-processing.

In the medical field, the printer can be used to fabricate anatomical models with different textures and colors, aiding in surgical planning and patient education. In education and research, the Palette 300 offers a powerful platform for exploring material science and advanced manufacturing techniques.

Looking Ahead: The Future of Multi-Material Printing

AtomForm’s Palette 300 represents a significant leap forward in multi-material 3D printing. By addressing the limitations of traditional extrusion systems, it empowers users to create more complex, functional, and aesthetically refined parts. As additive manufacturing continues to evolve, innovations like the Palette 300 will play a key role in expanding the technology’s reach and capabilities.

With its debut at CES 2026, AtomForm has positioned itself as a leader in the next generation of 3D printing solutions. The Palette 300 is expected to ship in Q3 2026, with pricing and pre-order details to be announced in the coming months.

Source: 3D Printing Industry