The U.S. military is no stranger to innovation, but its latest push into additive manufacturing marks a significant shift from experimental research to real-world deployment. 3D printing is no longer confined to labs—it’s now being scaled up to meet the complex demands of defense logistics, maintenance, and battlefield readiness.

Defense 3D Printing Moves Beyond the Lab

For years, the Department of Defense (DoD) has explored 3D printing through pilot programs and research initiatives. Now, the focus is on scaling these technologies to support operational needs. The U.S. Army, Navy, and Air Force are all investing in additive manufacturing to produce spare parts, tools, and even entire components on demand.

One of the key drivers behind this shift is the need for rapid, decentralized production. Traditional supply chains can be slow and vulnerable, especially in remote or contested environments. 3D printing offers a way to produce critical parts on-site, reducing downtime and increasing mission readiness.

Key Applications in Military Additive Manufacturing

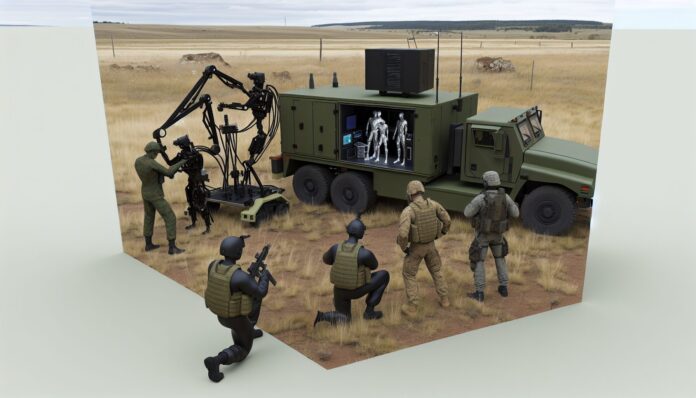

Defense applications of 3D printing are diverse and growing. The Army has deployed mobile additive manufacturing units capable of printing parts in the field. These units can fabricate everything from vehicle components to medical devices, directly supporting troops on the ground.

The Navy is using 3D printing aboard ships to produce replacement parts during missions, minimizing the need for large inventories. Meanwhile, the Air Force is leveraging additive manufacturing to repair aging aircraft, extending their service life and reducing maintenance costs.

In one notable example, the Air Force successfully 3D printed a metal replacement part for the F-22 Raptor, a fifth-generation stealth fighter. The part, which is no longer manufactured, was reverse-engineered and printed using a high-performance metal alloy, demonstrating the potential of additive manufacturing to address obsolescence issues.

Challenges in Scaling Up Military 3D Printing

Despite its promise, scaling up 3D printing in defense comes with challenges. Certification and quality assurance are critical, especially for mission-critical components. The military must ensure that printed parts meet strict performance and safety standards.

Cybersecurity is another concern. As 3D printing relies on digital files, protecting design data from tampering or theft is essential. The DoD is working on secure digital thread systems to track and verify every step of the additive manufacturing process.

Training and workforce development are also key. Operators need specialized skills to run and maintain 3D printers, interpret CAD files, and perform post-processing. The military is investing in education and partnerships with industry and academia to build this expertise.

The Future of Additive Manufacturing in Defense

Looking ahead, the role of 3D printing in defense is set to expand. The DoD’s Additive Manufacturing Strategy outlines a vision for integrating AM across the entire defense ecosystem—from design and prototyping to sustainment and logistics.

Emerging technologies like multi-material printing, large-format systems, and AI-driven design optimization will further enhance capabilities. The goal is to create a flexible, resilient manufacturing infrastructure that can respond quickly to evolving threats and operational needs.

As the military continues to scale up its use of 3D printing, the line between research and deployment is blurring. Additive manufacturing is no longer a future concept—it’s a present-day force multiplier for defense.

Source: Forbes