As the 3D printing industry continues to evolve, material extrusion remains one of the most widely adopted and versatile additive manufacturing technologies. Looking ahead to 2026, experts are forecasting significant developments in this segment, driven by innovation, market demand, and expanding applications across industries.

Material Extrusion 3D Printing: A Market Overview

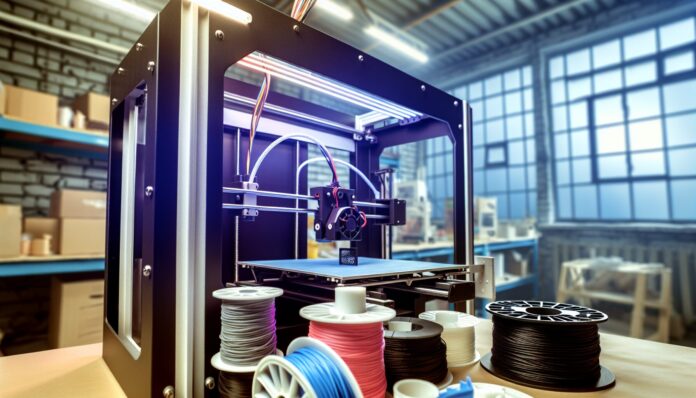

Material extrusion, often referred to as Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM), is the most accessible form of 3D printing. It works by extruding thermoplastic filament through a heated nozzle, layer by layer, to build parts. This technology has become a staple in both consumer and industrial markets due to its affordability, ease of use, and growing material options.

According to industry analysts, the material extrusion market is expected to see steady growth through 2026. This growth is fueled by increased adoption in education, prototyping, and even end-use part production. The technology’s low entry cost and expanding ecosystem of open-source hardware and software continue to attract new users and businesses.

Key Trends Shaping the Market by 2026

Several trends are expected to define the material extrusion landscape over the next few years:

- Industrialization of FFF: More companies are investing in high-performance FFF systems capable of producing functional parts with engineering-grade materials. This shift is blurring the line between prototyping and production.

- Material Innovation: The range of printable thermoplastics is expanding rapidly. By 2026, expect to see more high-temperature polymers, carbon fiber-reinforced filaments, and sustainable bioplastics entering the market.

- Automation and Workflow Integration: As businesses scale up their 3D printing operations, automation in post-processing, part removal, and print monitoring will become essential. Integration with digital manufacturing workflows will also be key.

- Software Advancements: Slicing software is becoming more intelligent, with features like adaptive layer height, real-time error detection, and AI-driven print optimization. These tools will improve print quality and reduce failure rates.

Applications Expanding Beyond Prototyping

While prototyping remains a core use case, material extrusion is increasingly being used for end-use parts, tooling, and jigs and fixtures. Industries such as automotive, aerospace, and healthcare are leveraging FFF for low-volume production and customized components.

In the medical field, for example, FFF is used to create patient-specific surgical guides and prosthetics. In manufacturing, it enables rapid production of custom tools and replacement parts, reducing downtime and costs. As material properties improve, the range of viable applications will continue to grow.

Challenges and Opportunities Ahead

Despite its advantages, material extrusion faces challenges that must be addressed to unlock its full potential. Print speed, surface finish, and mechanical properties still lag behind some other 3D printing technologies. However, ongoing R&D is closing these gaps.

Opportunities lie in education, where FFF printers are becoming standard tools in STEM programs, and in emerging markets where affordable manufacturing solutions are in high demand. Additionally, the push for sustainability is driving interest in recyclable and biodegradable filaments, opening new avenues for innovation.

As we approach 2026, material extrusion is poised to remain a cornerstone of the additive manufacturing industry. With continued advancements in hardware, materials, and software, this technology will play a critical role in democratizing production and enabling on-demand manufacturing worldwide.

Source: 3DPrint.com