As the world seeks cleaner and more affordable energy solutions, 3D printing is emerging as a powerful tool to reshape how we generate and distribute power. Recent innovations suggest that additive manufacturing could be the key to building cheaper, more efficient energy systems.

3D Printing for Energy: Unlocking Efficiency Through Design

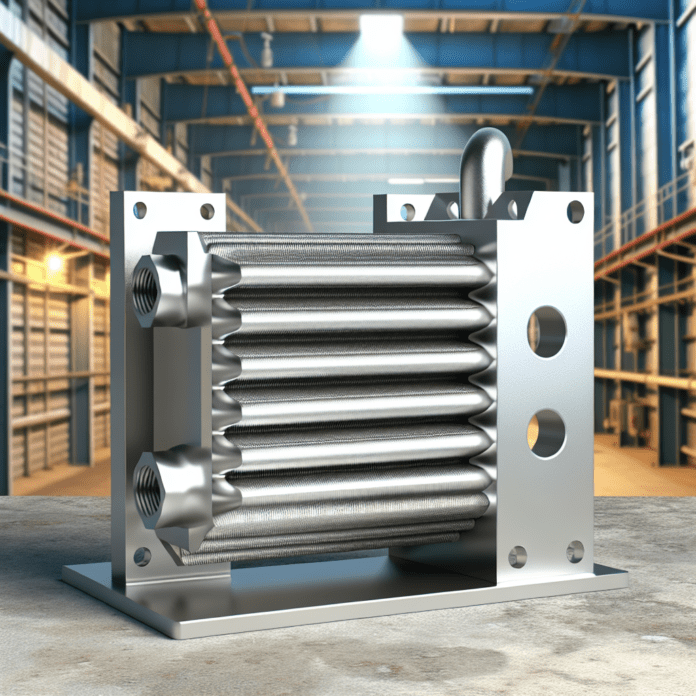

One of the most promising applications of 3D printing in the energy sector is the production of compact heat exchangers. These components are critical in systems like power plants, air conditioners, and engines. Traditional manufacturing methods limit the complexity and efficiency of their internal structures, but 3D printing removes these constraints.

Using additive manufacturing, engineers can create intricate lattice structures and optimized geometries that maximize heat transfer while minimizing material usage and volume. This leads to smaller, lighter, and more efficient components that can operate at higher temperatures and pressures—conditions that are key to improving the efficiency of energy systems.

Reducing Costs With Additive Manufacturing

Conventional heat exchangers are expensive and time-consuming to produce due to their complex internal geometries. They often require multiple parts to be welded together, increasing the risk of leaks and structural weaknesses. 3D printing enables the production of these parts as a single, consolidated piece, reducing assembly time, labor costs, and the potential for failure.

Additionally, additive manufacturing allows for rapid prototyping and iterative design, which accelerates innovation cycles. Companies can test and refine heat exchanger designs quickly, leading to better-performing products brought to market faster. This agility translates into cost savings not only in manufacturing but also in operational efficiency and maintenance.

The Role of Advanced Materials and High-Temperature Applications

Another advantage of 3D printing is its compatibility with high-performance materials. Metal additive manufacturing techniques like laser powder bed fusion (LPBF) or electron beam melting (EBM) can produce components from nickel-based superalloys and other heat-resistant metals. These materials are essential for applications in gas turbines, nuclear reactors, and concentrated solar power systems, where components must withstand extreme temperatures and corrosive environments.

By leveraging these materials, 3D-printed heat exchangers and other energy system components can operate at higher thermal efficiencies. This means more energy output for the same amount of fuel—whether fossil-based or renewable—leading to lower energy costs and reduced emissions.

Compact, Modular Power Systems: A New Frontier

3D printing also enables the design of compact, modular energy systems. For example, small-scale nuclear reactors or microturbines can benefit from integrated components that are customized for specific applications and locations. These modular systems are easier to transport, install, and maintain, making them ideal for remote areas or decentralized energy grids.

Such systems could play a significant role in the transition to renewable energy by providing backup power or stabilizing intermittent sources like solar and wind. Their reduced footprint and cost make them attractive for both industrial and residential use.

Challenges and the Road Ahead

While the potential is enormous, there are still challenges to overcome. Certification and regulatory approval for 3D-printed components—especially in critical energy infrastructure—can be a lengthy process. Material properties must be thoroughly tested, and quality control must be rigorous.

However, as the technology matures and more success stories emerge, the energy sector is likely to adopt 3D printing more widely. With continued investment in R&D and collaboration between manufacturers, engineers, and policymakers, additive manufacturing could become a cornerstone of sustainable, affordable energy systems.

In conclusion, 3D printing is not just transforming how we make things—it’s reshaping how we power the world. By enabling efficient, compact, and cost-effective components, additive manufacturing is poised to drive down the cost of energy and accelerate the shift to cleaner, smarter power systems.

Source: Core77